WhatsApp)

WhatsApp)

Cylindrical grinding was developed to achieve a perfectly round shape. Outofround grinding however gives the workpiece a defined noncircular shape with the grinding process perfecting the final surface quality. Examples of noncircular shafttype components include camshafts cam discs and pump shafts

In machines for grinding cam shafts as heretofore made the various operations of the machines were controlled by an operator so that it was impossible for one operator to run more than a single machine. With this machine the operator places the work in position in the machine and starts the machine whereupon the entire cam shaft is ground to

Cam shaft grinding for sale Shredding chamber dimensions 8500x550 mm with n2 counterrotating hexagonal shafts fitted with n28 blades with a thickness of 30 mm 1 hook double spaced to 60mm. requirement 7500 kW weight of the machine ca. 2500 t dimensions of the machine ca. 500 x 350 x H350 m Derjlfjl Cam grinding machine with

Cam shafts grinding machine assetcarecoin Distributor Supplier of Cam Shaft Grinding Machine my question is how were cams and cam shafts made back in the these machines can copy the original cam . More Delta Camshaft. Grinding your custom Camshaft Camshaft Grinding Process The first step is to set up the cam grinding machine for the

CNC Cam Lobe Grinding Machine is a very unique and Economical solution for Cam grinding. It is very compact high precision very stable for high accuracy production runs of cam shafts with convex and concave cam forms

Nov 0 2013 SERVICE Overhaul Centerless Grinding Machine and Automation System was started. Oct 0 2017 Upgrade Quality System to IATF 16949 Japan Factory

Cylindrical Grinding Machine for Complete Machining of Long Complex Cam Shafts PRODUCT The SCHAUDT CamGrind XL cylindrical grinder comes with two slides making it the perfect solution for costeffective complete machining of long complex workpieces up to 1300 mm

The master cam roller is then aligned to the next master cam. Wheel wear from cam to cam is avoided by turning the work table slightly. To learn more about cam grinding or other types of precision grinding machines call Maximum AdvantageCarolinas. Our Fort Mill SC office serves clients worldwide by providing the very best grinding equipment

200951As some cam cores became difficult to locate we began manufacturing cams from bar stock in the 1990s. We have become the nations leading supplier of new replacement OEM and aftermarket cam shafts cam lobes cam muffs and cam sections for industrial engines. For our new production many operations are required before and after heat treat

Evolution of Performance Camshaft Grinding Finishing. Originally the grinding machine mist collectors were mounted directly on the machine enclosures. However it was determined that the mist collectors electric motors caused a slight amount of vibration that resulted in a small bit of measurable chatter in the ground camshafts. Now

Grinding machine for working metal. Overview. Cam grinding Cam shaft grinding. In order to grind cams or other asymmetric forms on shafts a round grinding machine can be used also in combination with an additional automation axis and an appropriate controller

Cam Shaft EH Precision India private Limited. can provide lathe parts cnc turned parts mechanical parts with Japanese Quality from India. After doing all processing with NC lathe multistep grinding is performed with centerless grinding machine. The outer diameter tolerance is and in order to achieve such accuracy E H

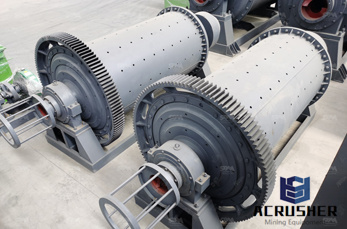

Cam wet ball mill machines Ristorante Erbaluce. cam shaft and trigger wet ball mill machine. A Ball mill or pebble mill is a milling machine is a milling machine that is equipped with hallow cylinder containing balls so that it can be rotated along its longitudinal axis

Cylindrical grinding machine external cylindrical grinding machine internal cylindrical grinding machine centering grinding machine center grinding machine Max shafts diameter 240 mm max grinding length 310 mm Bbm0rovoew jaw chuck sie 160 mm Grinding wheels diameter mm Dimensions H1840 mm Weight 1802 kg more

Camshaft grinding machine india Cam Grinding Machines Manufacturers Suppliers Dealers. Cam Grinding Machine We are Madurai Tamil Nadu India situated widely accepted and acclaimed names actively indulged in the business of exporting distributing trading and supplying a premium quality assortment of Cam Grinding Machine. Get price

2 Engine Cam. With years of experience in dealing with engine cams and camshaft repair we have a complete and full understanding of how the engine cam works whether for racing performance a diesel engine or an antique vehicle

World market leader in CBN grinding and a source of inspiration for the entire industry. Doublewheel surface grinding machines. Cutting tool grinding machines. Profile and cutoff grinding machines. Lean Selection. Tough shafts made easy to grind. Read more Precision production for the perfect ride

The Landis LT1e grinding machine incorporates the technology of larger machines into a smaller imprint providing unrivaled quality and cycle time standards for todays shorter 4 and 6cylinder camshafts as well as for shortrun processing of concentric and nonconcentric single and multidiameter shafts

201936Cam Making Made Easy. by Gram Meek UK Many builders have gone down this route but have resorted to building specialistgrinding machines to rectify this distortion. ETW also states in his construction article on the Seal that by far the quickest way to manufacture a camshaft was to make all the inlet and all the exhaust cams together

Crankshaft or crank pin grinders also resemble cylindrical grinder but are engaged to grind crank pins which are eccentric from the centre line of the shaft. Cam and camshaft grinders are essentially subsets of cylindrical grinding machine dedicated to finish various profiles on disc cams and cam shafts

Cam Shafts Grinding Machine MC Machinery. 91 636 used Camshaft Grinding Machine 23 01 2020 from certified dealers from the leading platform for used machines Cookies make it easier to offer our services By using our services you acknowledge and agree to our use of cookies

External cylindrical grinding machine camshaft CNC highperformance SN 204 SN 208 Make a request external cylindrical grinding machine The GC20Mi is a highspeed camshaft grinding machine This CBNcapable machine has a small footprint and features the TOYODA STAT BEARING floating plate and Toyoda GC50 controls 247 Online

used Cam Shaft Grinding from certified dealers from the leading platform for used machines

Texas Speed Performance is a leader in LS and Gen 5 LT camshafts All of our camshafts are ground inhouse using our stateoftheart Landis CNC camshaft grinders. Every shelf stock camshaft we offer is tested on our SuperFlow 902 engine dyno for guaranteed results Inhouse cam grinding allows us to develop and test our camshafts in the same day removing the guess work for our customers

WhatsApp)

WhatsApp)