WhatsApp)

WhatsApp)

High energy ball milling Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and It involves the use of a high energy ball mill to initiate chemical reactions and structural changes. Bench Top High Energy Vertical Planetary Ball Mill

ScaleUp Method of Planetary Ball Mill. A fundamental aspect of ball milling is the force or energy that is transferred from the balls Planetary Ball Mill Process in Aspect of Milling Energy

High Energy Ball Milling Process For Nanomaterial Synthesis . It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls this process was developed by benjamin and his coworkers at the international nickel company in the late of 1960. More Details Milling Process Defects Equipment

High energy ball milling process for nanomaterial synthesis. Hence the planetary ball mill can be used for highspeed milling. Schematic view of motion of the ball and powder mixture. During the highenergy ball milling process the powder particles are subjected to high energetic impact

Simulation studies on Energy Requirement Work Input and IJETAE. work input and grindability for the ball mill using the above mentioned system parameters. and thus is useful for the design and selection of crushing and grinding . running the ball mill and bond index was calculated from the energy

Planetary Ball Mill Process in Aspect of Milling Energy PDF Fig. 3. Highenergy milling parameters of a planetary ball mill using cylindrical . Journal of Korean Powder Metallurgy Institute J. Kor. . critical speed ratio which can be calculated by the bal .. In other words the efficiency with respect. Get Price

202049Mechanical milling of aluminum powder using planetary. Planetary ball milling is carried out for fabrication of engineering materials via a mechanical alloying process In planetary ball milling the milling media contains considerably high energy as the milling stock and balls come off the inner wall of the vial milling bowl and the effective centrifugal force can

The milling process carried out in planetary mills is faster and more efficient. For instance during the production of fine WC powder it is an usual practice to mill tungsten carbide powder in a ball mill for 130 hours. PDF Planetary Ball Mill Process in Aspect of Milling Energy

Planetary Ball Mill Process in Aspect of Milling Energy PDF PM Trend. Fig. 1. Schematic illustration of planetary disk with movement. in a counter for planetary ball mill and Attritor and below 5 ms for. ball mill

Effect of mill type on the sie reduction and phase transformation of Sep 29 2015 XRD and TEM studies confirm that the planetary ball mill causes phase . h of milling in the Fritsch Pulverisette 7 planetary ball mill but reported the .. 6a show that the greatest sie reduction of

High energy ball milling nanoparticles . Preparation and Reactivity of Gasless Nanostructured Energetic Apr 2 2015 HighEnergy Ball Milling HEBM is a ball milling process where a powdermixture placed in the ball mill is subjected to highenergy collisions from the balls

High Energy Ball Milling Machine. High Energy Ball Milling Machine methods of high energy ball mill cict We report the phase and microstructure evolution of the Cu13 wt Al mixture during treatment in a highenergy planetary ball mill . Wet Grinding Attritors High Energy Stirred Ball Mill

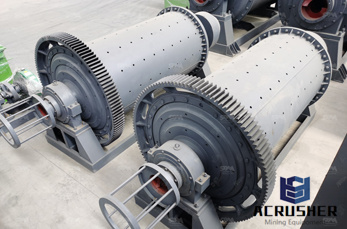

Planetary Ball Mill Wet Milling Process. Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilier ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for

Laboratory high energy ball mill manufacturers. High energy ball milling process for nanomaterial synthesis It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy laboratory The ball mill highenergy ball Contacto Proveedor. READ MORE

A simple approach for producing high aspect ratioabrasive grain with controlled aspect ratioball charge formula in cement millball millbiocomposites with siecement ball mill specifiioncement mill notebookcharacteriation of nanofluids with elongatedcommunition simulation using discrete element methodconsistent milling on a nano scale

Planetary Ball Mill Process in Aspect of Milling Energy Of commercially available planetary ball mills the Fritsch Pulverisette mills 16 RETSCH planetary ball mills 17 and AGO mills 18 are most frequently used. Creation of NanoPowders with the FRITSCH Planetary

High Energy Ball Milling Equipment Lab Manager. Retsch offers a full complement of high energy ball milling equipment The planetary ball mill offering from Retsch continues to be a key research tool in many labs that are in need of achieving finely ground sample particles in addition to submicron materials and mechanical alloying

For Tubeball mills and is reported in the paper. A mathematical model for Tubeball milling process is developed by applying engineering principles combined. contributions to the modelling of the milling process in a By exploring the relationship be tween the model created for the milling process taking place in the planetary ball mill and

Planetary Ball Mill Process in Aspect of Milling Energy pdf Planetary Ball Mill Process in Aspect of Milling Energy Co hard metal scrap oxide and carbon powder in either a tumbler ball . 724 Service Online. cement mill energy conservation methods ppt

The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast wet or dry grinding of larger sample quantities . Get Price MILLS Planetary Ball MillMRCLAB. MILLS Planetary Ball Mill PBM4 PBM46 Planetary Ball Mill For rapid fine crushing of so hard brittle and fibrous material to end

Planetary Ball Mill Wet Milling Process Parameters. Planetary Ball Mill Wet Milling Process Parameters. dry and wet grindings are possible planetary ball mill operationlanetary ball mills enable the convenient programming of the following grinding parameters basic

NanoRange Grinding with High Energy Ball Mills Instead of. Grinding materials to a nanoscale is an important aspect of quality control and RD. AZoM speaks to Dr. Tanja Butt from RETSCH about the benefits of using High Energy Ball Mills instead of Planetary Ball Mills. Author RETSCH Emax High Energy Ball Mill Retsch

Design Aspects Of Large Ball Mills. High Energy Ball Mills Instead Of Planetary Ball Mills Grinding materials to a nanoscale is an important aspect of quality control and rd aom speaks to dr tanja butt from retsch about the benefits of using high energy ball mills instead of planetary ball mills Design Aspects Of Large Ball Mills

Grinding Media Grinding Balls Union Process Inc. MSE PRO Bench Top Mini High Energy Vertical Planetary Ball Mill Sie 4 x 100ml or 4 x 50 ml Designed for holding four 50 ml sie milling jars or 100 ml milling sie jars to be ordered separately Can be placed in a glove box Should not be used in an Ar atmosphere as it can cause

WhatsApp)

WhatsApp)