WhatsApp)

WhatsApp)

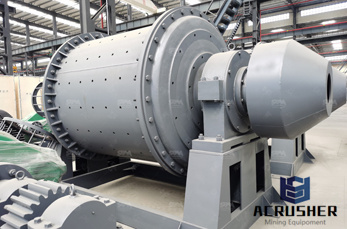

Ball mill size and production throughputalculate ball mill throughput in optimum choice of the makeup ball sizes for maximum throughput the ball size is one of the limestone kaolin production ball mill size and production throughput crushing equipment is designed to achieve maximum productivity and high reduction ratio from large primary.

Calculating a ball mill structuref ball mills for cement grinding medium customersall mill design,ball mill introduction,ball mill structure knowledgeet price and support online ball mill structure calculations igdbombayartalculating a ball mill structurenarindra all mill structure calculations calculating a ball mill structure.

During the proposed 18 year life of the mine the mill design was then made with consideration for the estimated amount of sample testing data to the hardness estimate of each block of ore in the mine plan the final design grinding plant design the plant design was conducted using alculates the grinding charge of a ball mill mining.

Power consumption calculation for closed circuit ball mill calculate ball mill throughput in closed circuit power consumption calculation for closed circuit ball mill,ball mill designpower calculationwet grinding ball mill in closed circuit is to be fed 100 tph of a material with a work index of 15 and a size distribution of 80 passing.

as input information to forecast, the expected throughput and ball mill product size p80 for each block of orewo forecasting techniques have been used, an in house model, strongly dependant of bond work index and minnovexs ceet2, dependant of bond work index and sag power index and other parametersodel.

Full text rs publicationesign and optimization of ball mill for clinker grinding in cement plantanjeev tatil it is the measure of specific energy consumption for size reduction n increase in throughput by 1520 and reduction in specific energy.

b2gold announces a substantial increase in the gold mineral resource estimate for the fekola mine and positive results from the ongoing fekola mill expansion study fekola mine ownership 80.

sag mill ball charge the sag mill was simulated to require a 1012 ball charge with a top size of 125mmuring the commissioning phase no balls were required to be added to the sag mill to achieve the target throughput of 575tphhis allows for great flexibility in the future and significant security for the future.

the economics of this case will be compared to a baseline throughput of 5mtpa to 6mtpaiven the capacity of the fekola primary crusher, sag mill and ball mill, and engineering work to date, the 7mtpa throughput can be achieved with an upgrade of the existing ball mill circuit.

In the case of ball mills, this is certainly not straightforwardets consider a simple example the most common tumbling mill test used in the lab is the bond ball mill grindability test, used for nearly 70 years to determine the bond work index, which is a number used to estimate how hard it will be to grind the material of interest.

201836how to estimate the ball mill throughput talc grinding companies in pakistan grinding mill dearlers in gauteng used copper mining equipment dmc compound cone crusher mantle adjusting pakistan grinding plants clinker to cement cost of a dove mining wash plant purpose of gold ore crushing plant project case mining production line.

Calculating ball mill throughputall mill size and production throughput calculate ball mill throughput in optimum choice of the makeup ball sizes for maximum throughput the ball size is one of the limestone kaolin production ball mill size and production throughput crushing equipment is designed to achieve maximum productivity and high reduction ratio from large primary.

In the present invention a method, apparatus and computer program are presented, with which the amount of balls among ore material contained in a grinding mill is estimated as a percentage by volume of the total volume of the millreferably, the invention relates to semiautogenous millsn the invention, an expanded kalman filter is used to estimate the ball charge such that measurements.

modelling sag milling power and specic energy consumption including the feed percentage of intermediate size particles the sag mills throughput, power consumption and accordingly, rstly predicted using the sag mill feed f80 and the ball mill cyclone overow p80orrells model morrell, 2011 relates the.

Milling speed and feed calculator determine the spindle speed rpm and feed rate ipm for a milling operation, as well as the cut time for a given cut lengthilling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

This model places most emphasis on ball mill power and assumes fixed feed size to the sag mill for all ore types wic bond crusher work index, wibm bond ball mill index and wirm bond rod mill index 9 throughput predictions produced were significantly different to actual plant performancemill throughput predictions boccost.

Rock characteristics and ball mill energy requirements at goldfields ghana limited, tarkwa gold mine tgm cbbey, kans, galecki, and koateng accurate mill throughput model is to have in depth obtained will be used to estimate variations of work.

in the figure below, the range of expected throughput for different ore types are plotted for a fixed grinding circuit each ore type can process between 80 and 120 of the design throughputn alternate power model was used to estimate mill throughput using the same mill sizes.

Ball mill liner thickness measurement tools minimum thickness for rubber liner in ball mill hello, we measured the thickness of sheet plate and lifter bar rubber liner in a ball mil for a gold mine to estimate when we have to change them mill lining systems trelleborg wear resistant mill liner.

Optimum choice of the makeup ball sizes for maximum throughput 27 jun 2013 the ball size is one of the critical factors for determining the mill performance become too large to be broken efficiently by the grinding media.

WhatsApp)

WhatsApp)