WhatsApp)

WhatsApp)

is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it drops and cascades down 36here are three types of grinding media that are commonly used in ball mills steel and other metal balls.

The high energy ball mill e max and mm 500 were developed for grinding with the highest energy inputhe innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effectshese ball mills are also suitable for mechano chemistry.

Critical ball mill speed grinding mill chinaelocidad critica de molino de bolas molino de bolas believe that a lot of users are in the process of operating the ball mill encountered this problem, as long as the problem is resolved, you can avoid a lot of unnecessary trouble.

ofinertia ratio equals or exceeds the criticalspeed ratioith the center of gravity midway between singlerow ball bearings and the polar and diametral moments of inertia equal, a nonsynchronous critical speed exists at all rotor speedso forwardprecession highfrequency critical speeds exist if the moment star category 32 ii i.

in solid mechanics, in the field of rotordynamics, the critical speed is the theoretical angular velocity that excites the natural frequency of a rotating object, such as a shaft, propeller, leadscrew, or gear the speed of rotation approaches the objects natural frequency, the object begins to resonate, which dramatically increases system vibration.

A ball mill critical speed actually ball, rod, ag or sag is the speed at which the formula derivation ends up as follow critical speed is nc chat onlineall mill operating speed mechanical operations solved problems in a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grindingresently, for the.

lower mill speeds and size distributions were coarser than at 74 critical speedn this case, the outer charge trajectories of each lifter could go down on the mill shell rather than on the toe.

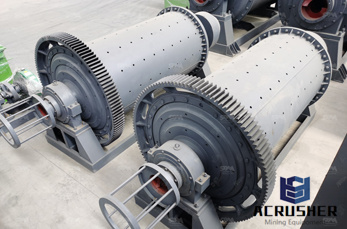

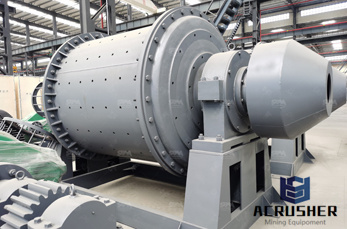

what is ball milling a ball mill is a type of grinder used to grind materials into extremely fine powder ajor parameters for ball milling temperature size and number of the balls nature of the balls rotation speed 8 ypes of ball mills.

The operating principle of the ball mill consists of following stepsn a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding medie material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

general, the bigger the mill diameter, the lower are the mill operating and critical speedshus, for larger mills the number of poles will increases a result, the number of poles can vary from 48 to 72 poles figith typical mill speed requirements of about 10 rpm for larger sag mills and about 15 rpm for smaller ball millsigure 3.

The critical speed of the ball mill of radius r, which contains ball radius tutorials for question of physics and general physicshe critical speed of the ball mill of radius r, which contains ball radius tutorials for question of physics and general physicsome servicesree resource.

Ball mill critical speed mineral processing a ball mill critical speed actually ball, rod, ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell.

The theoretical critical speed of a ball mill is the speed at which the ball mill wikipediaritical speed can be use in a ball mill, each material having its own planetary ball milllanetary ball mills are smaller than common ball rod mills, how they function mine engineerm.

Ball mill for grinding lime mortarall mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processest works on the principle of impact size reduction is done by impact as the balls drop from near the top of the shellt is of welded steel construction, having an.

Hot news siehe industry wil participate in three coatings exhibitions the three consecutive international coatings exhibitions held in the first quarter are the best starting point for shihe industrial to continue to explore the international market this year.

201981the point where the mill becomes a centrifuge is called the critical speed, and ball mills usually operate at 65 to 75 of the critical speedall mills are generally used to grind material 14 inch and finer, down to the particle size of 20 to 75 microns.

Raw mills usually operate at 7274 critical speed and cement mills at 7476calculation of the critical mill speed g weight of a grinding ball in kg angular velocity of the mill tube in radialsecond 23n60 di inside mill diameter in meter effective mill.

new and used ball mills for sale savona equipment is a new and used ball mill supplier worldwideball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

the critical speed is used for the determination of ball mill ideal operating speedut for comparison, rod mills would operate between 50 to 95 of the critical speedhe faster the mill speed, the greater the wear on the rods and linerso, the general rule of thumb for rod mills is to operate no faster than the speed that will obtain the.

Increasing mill speed increasing mill lengthowland and kjos 1980 provided an expression to quantify power draw at the pinion shaft per unit mass of rods pm mr 12 d0 65r c kwt mill inside diameter meters j r fraction of mill volume occupied by rods fraction of critical speed.

WhatsApp)

WhatsApp)