WhatsApp)

WhatsApp)

the future of grinding industry is here strong production bases guarantee the normal production of grinding mills and quick deliveryis is sbm power.

vertical roller mill for cement, clinker, slag, clirik vertical roller mill for grinding slag, cement clinker, fly ash, quartz, feldspar, calcite, t carbon black grinding mill, processing line till now in the world, there have no mature carbon black grinding technologyter serveral years res.

Vertical roller mill brandshuguang parametersee form vertical roller mill is short for grinding, which is used for cement raw material, cement clinker, slag and cinder millt has the characteristics of simple structur.

Here, we mainly introduce development history of vertical grinding millertical roller mill is also called vertical grinding mill, roller mill and vertical roller millhe first vertical mill was invented in the 1920s in germany while the first vertical mill used for cement production appeared in 1935 in germany.

The power ingesting of a grinding process is 5060 in the cement production power consumptionhe vertical roller mill vrm reduces the power consumption for cement grinding approximately 3040.

Leading manufacturer of chinese cement machinery large mining mill production and export company china rotary kiln production champion enterprisengfei group,global export base of kiln and energysaving grinding mill equipment, is a model enterprise of.

Vertical roller mill operation ince the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following.

Such an improved performance in cement grinding operations encouraged the research studies on ore grinding applicationsithin the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant.

roller mill for cement grindingverview vertical roller mill is a kind of grinding machine for cement raw material cement clinker slag and coal slag.

vertical roller mill has many different forms, but it works basically the samell of these forms of machine comes with roller or the equivalent of roller grinding parts, and roller along the track of the disc at the level of circular movement imposed by.

loesche supplies four vertical roller mills vrm for cement plants of pakistans second largest producer in sinomas decision to again choose the grinding plants of the vertical roller.

China vertical cement raw mill supplier, roller mill for cement grinding, clinker grinding mill, mill disc mm, 2 3 4 roller mmven there are different kinds of vertical roller mill with different models and manufacturers, the working principle of the vertical roller mill is almost the same.

vertical roller mill for cement industryn cement plant, vertical grinding mill is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etcimestone is the largest amount of raw material during cement.

finish grinding of portland cement, slag and blended cementshe mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the ok cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag.

energyefficient technologies in cement grindingit also has the flexibility of a vertical roller mill in grinding of different materials larger angle of nip draws the material bed into the grinding gap and reduces wear as compared to vertical roller millshe recirculation of material within a vertical roller mill is very high.

Globally established loesche vertical roller mill for use in a jul 26, 2017 the new mill will be used in the new line 3 of the cement plant in hub a vertical roller mill of type lm 56 cs for grinding cement clinker to.

Gebrfeiffer to supply the worlds largest vertical roller mill for cementolcim brasil s has awarded the spanish epc leader cemengal a contract to supply a stateoftheart cement grinding station to increase the capacity of its.

vertical roller mill used for coal, cement, limestone vertical roller millertical roller mill is a type of lm series grinder mill used in cement industry, coal grinding industry, clinker grinding.

lm vertical roller mill grinding systemwithout hot air raw materials in the hopper are lifted by elevator and pass though airlock device, enter into the grinding chamberround by the lm grinding mill, powders are collected and transported to silohe advantages of this system are that it has simple structure, low investment and operation.

vertical roller mill overviewhe vertical roller mill has become the preferred equipment for cement industry raw material grinding, is estimated to have more than 600 sets of productionarge vertical mill capacity has reached 600th, the transmission power of 5000kwt the beginning of the 90s the mill in cement grinding and have new.

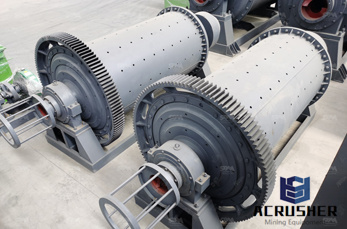

Raw mill is widely used in cement plantaw mill is the key equipment for secondary grinding after crushingnd it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grindingaw mill is mainly used in grinding raw materials and end products in cement plantt is also suitable for various ores and.

Cement grinding vertical roller mill in swedenindia cement grinding vertical roller mill in sweden fl contact fl iset pricerinding trends in the cement industry cement limet is somewhat surprising that the number of different grinding processes and mill placed another order for loesche vertical roller mills for the cement plant.

in our country, the promotion and use of vertical grinding mill seems a bit slowue to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity gauguin is let very favour of cement.

Grinding rings and hollow balls for e mills rolls and table segments of raymondce mills abrasion is the most dominant factor in determining the working life of vertical mill grinding elements and the group supplies three types of alloy to cope with the different abrasion conditions.

WhatsApp)

WhatsApp)