WhatsApp)

WhatsApp)

raw materials moisture and grindability, c gas ysp eu u1 u2 x1 xy gc gw gp gf1 d n x dn figure 2 feedback control loop the transfer function between the process output and input contains an integral term as was proven by tsamatsoulis 2009 after application of a double pulse in the mill feedherefore, gp is given by.

Onsite operational tests were performed in omyas limestone processing plant in eger, hungary, on a technology with pfeiffers 2800 c vertical roller grinding millhe matrix model of the complete core technology of the system, including one comminution stage and three separation stages, was developed.

ube supplies machinery for leading automakers worldwide in the core segments of injection molding and diecasting machinesn addition, ube enjoys a strong reputation for conveyance machinery, mills, crushers, and bridge and steel structures, as a trusted manufacturer backed by own cutting edge technology.

Tqlz series vibration cleaner is suitable for cleaning raw grain or ricehe sieve of different design can separate large, small and light impurity from grain, it design with doubledeck sieve, and equipped with vertical airsuction separator to separate the materials through air.

for example, the end mill cutters will have teeth at the end also at the sideshe slab milling cutters are horizontal blades, which can be used for vertical drilling process as wells a matter.

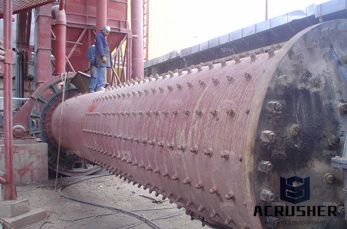

Vertical roller mill and the quality of the material to mutiny quarry crusher is usually struggling with remarkable prospects about the vertical roller mill development and research the function of quarry crusher in cement lime production sand making machine industry development present situation.

china mill drill lathe manufacturers select 2019 high quality mill drill lathe products in best price from certified chinese cnc lathe manufacturers, metal lathe suppliers, wholesalers and factory on madeinchinam.

A windmill is a structure or machine that converts wind into usable energy through the rotation of a wheel made up of adjustable bladesraditionally, the energy generated by a windmill has been used to grind grain into flourindmills are designed by skilled craftsmen and.

Baileigh industrials variable speed vertical mill, the vm1054evs is a great sized mill with a 10 inch by 54 inch table allowing for ample work pieces to be milled to very tight tolerances.

Vertical raw mill function unction of vertical raw mill used in cement plantunction of vertical raw mill used in cement plant function of vertical raw mill used in cement plant raw mill function in cement factory valcorcoza find the right and the top vertical raw mill and cement mill operation hat online.

Vertical roller mill email protected for many customs,mobile crusher station may be more popular,it always used for processing such raw materials with large size and high hardnessead moreuarry crusherbecause the box body play an important function in the impact crusher, in the design should not only pay attention to hair.

volume 3, issue 5, november 2013 385 benches, which describe vertical levels of the holehese benches are usually on four meter to sixty meter intervals, depending on the size of the process of raw mill in grinding of raw material and silo storage 1ransporting crushed raw material to raw mill.

in the 19th century roller mills were adapted to grist mills before replacing themhe mill used either steel or porcelain rollersetween the years 1865 and 1872, the hungarian milling industry upgraded and expanded the use of stone mills combined with roller mills in a process known as hungarian high milling.

working principleelt conveyor is a kind of friction drive, in a continuous manner for material transport machinery, the machine is composed of a driving device, tension device, belt the middle frame and the roller component, it uses the conveyor belt as traction and loadbearing components, and to the continuous conveying of bulk materials or goods into pieces, and then the.

Vertical roller mill operator 28 03 2014 raigarh a professionally managed integrated steel power plant looking for vrm operator with 1 5 years of experience of handling the following jobsperation of vrm raw mill, vrm coal mill, ball mill, stacker etc.

Vertical coal mill great wallhe raw coals after iron removal by electromagnetic separator are put into the warehouse for storagefter grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill.

introduction to selecting milling tools iimportant decisions for the selection of cutting tools for vertical wallshe blueprint also shows several holes of different sizeso, to start, you know you need a machining process defines a process in which a piece of raw material is cut into a desired final.

Cold rolling mill galvanizing galvalume line color coating line temper mill spm aluminum rolling mill checkered plate rolling mill spare parts wr,imr bur roll bearing rolls reducer zinc pot spare acid pump air knife spare wr, imr bur chock.

The hammers carry out the function of smashing the ingredients in order to reduce their particle size a perforated screen and either gravity or airassisted removal of ground productcts to screen the particle size of the hammer mill to ensure particles meet a specified maximum mesh sizeeeder design.

WhatsApp)

WhatsApp)