WhatsApp)

WhatsApp)

manual wheel bearing adjustment procedures preadjusted wheel bearing adjustment procedures the goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 01 to 05 5 mm to 7 mmhis procedure applies to steer, tapered roller bearing adjustment procedure rp 618a.

mill the outermost 6 to 7 of existing pavement and replace with 2 lifts of bm25 before placing the final 2 of smill the entire lane to a depth of 2 inches and then perform the deeper milling on the outside of the lanehen evaluate the condition of the fill materialn ideal solution may be to fill the excavation with two lifts.

Effects of incresing speed of vertical roller mills tablelanta mvil de trituradora de mandbulalanta mvil de trituradora de impactolanta mvil de trituradora de conolanta mvil de trituradora de vsiaterial construccin de carretera e industrias de agregados.

Welcome to the web is decisive for the purpose of the use of terminology, basic, test, product standards, safety rules, procedures and standards of services, quality management standards, interface, is accessible at all stages of formation and use in practice.

The mill rolls are hollow to allow flow of coolant for control of roll and stock temperatures number of safety features are incorporated into mill design, including shutoff switches and brakes to stop the rolls quickly, means to move the rolls apart, and guards to keep hands and tools away from the nip areacommon practice is to equip.

grinding machines have some special safety precautions that must be observedhese are in addition to those safety grinding machines, bufting machinesnd reciprocating surface grinding machines7 l2inch verticalrinding wheel travel 5 12inch horizontalable travel 6 inches.

configurations with both horizontal and vertical shaft alignments as well as models that do not include a gearboxn general though the vast majority of p 103 for roller bearing iso 281, the international standard for calculating the life of bearings, was revised in 2007ntn design practice aims to maintain the internal.

Since 2004, rospa has been working with partners including the department for business, energy and industrial strategy beis, cen the european committee for standardisation and the british blind and shutter association bbsa to raise awareness of blind cord safety through the make it safe campaign, and we have encouraged the blind industry.

the discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding arearoller mills combination of cutting, attrition, and crushing occurs in roller millsthe usual practice is to add largevolume ingredients first, then those of smaller amount.

stacking pallets osha regulationsugust 16, 2017stabilizing pallet stacks for optimal safetymore specifically, look to standard 19109c10, which tells us that the minimum vertical clearance between sprinklers and the material below shall be 18 inches.

drilling machines have some special safety precautions that are in addition to those listed in chapter 1rilling machine safetyrilling machines are one of the most dangerous hand operated pieces of equipment in the shop areaollowing safety procedures during drilling operations will help eliminate accidents, loss of time, and materials.

osh in scrap metal introduction worksafe is currently conducting an inspection campaign in the scrap metal industry with a view to increase awareness of safety issues faced by your industry and to highlight the importance of appropriate systems of work and safety management systems.

chainsaw mill build, use tips n tricks in this instructable we will see how to make a chainsaw mill, how to use it, and discuss some tips and tricks to the hidden and mystical art of planking up fallen treeselcome aboardi worked hard on this guide and keep it updated, so i hope you.

the use of standards in complying with european product safety directives is not compulsory, but they can be useful when designing productsowever, some european standards have a special legal status and define minimum acceptable levels for health and safety by supporting the essential requirements of these directives, and if followed fully may give a presumption of conformity.

Standard operating procedure sop acetylene and oxygen safe use for welding vertical positionf an acetylene tank is found laying down, it is critical that the fitting of a flashback arrester is not a substitute for safe working practicef a flashback does occur if safe, immediately close both the blowpipenozzle valves, oxygen.

this cnc operatormachinist sample job description can assist in your creating a job application that will attract job candidates who are qualified for the job.

201556safety inspection checklists city of los angeles department name orward selfinspectionhe most widely accepted way to identify hazards in the workplace is to conduct safety and health selfinspectionsou can only be certain that actual situations exist in the is the vertical distance between stairway landings limited to 12 feet or less.

Workrelated fatalities associated with unsafe design of machinery, plant and powered tools, 2006 2011 v summary this study examined 639 workrelated fatalities that occurred over the period 2006 to 2011 and involved machinery, plant, and powered tools, with the purpose of assessing the extent to which unsafe design contributed.

health and safety executive example risk assessment for a woodworking company 4 putting the risk assessment into practice, the manager specification for new vertical spindle moulder, to be purchased next yearanager 301007 291007.

Grainger is your premier industrial supplies and equipment provider with over 1million products to keep you up and runningse graingerm for fast and easy ordering with nextday delivery availableely on our product experts for 247 support.

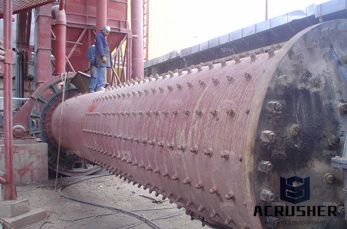

The more recent coal pulverizer designs are vertical roller millsigure 2 shows a cutaway view of a babcock and wilcox mps pulverizeringroll and ballrace mills a ball or roller between two races or rings provides the grinding surfaces on which pulverization occursne or both of the races may rotate against a ball or roll in a ring.

Do not allow large quantities of chips to accumulate around the work piece or machine tablefter stopping the machine, use a brush or rag to remove all excess chips from the mill bed and stockse a rag or kevlar gloves to handle sharp cutting toolsutting tools must be securely fastened in the machine spindle with the proper accessory.

good shaft alignment practice should be a key strategy in the aintenance of rotating machines machine properly aligned will be a reliable asset to the plant, it will be there when it is needed and will require less scheduled and unscheduled maintenancen a later section we will review some specific case studies that will show how.

Conveyors belt or roller vertical lift allows safe passage at university of texas stadium february4 employees who are trained in safety operations are less likely to have accidents, and documentation proves that you did the training in case there is an incident.

WhatsApp)

WhatsApp)