WhatsApp)

WhatsApp)

Onestep ball millingprepared nano Fe 2 O 3 and nitrogendoped graphene with high oxygen reduction activity and its application in microbial fuel cells Xingguo Guo Qiuying Wang Ting Xu Kajia Wei Mengxi Yin Peng Liang Xia Huang Xiaoyuan

201247Edgecarboxylated graphene nanosheets via ball milling InYup Jeona YeonRan Shina GyungJoo Sohna HyunJung Choia SeoYoon Baea Javeed Mmooda SunMin Junga JeongMin Seoa MinJung Kima Dong Wook Changab Daiac1 and JongBeom Baeka1 aInterdisciplinary School of Green EnergyLowdimensional Carbon Materials Center Ulsan National Institute of

porous alloy anodes at the same time. Through highenergy ballmilling the mixture of lowgrade silicon metallic tin and graphene a yinyang hybrid composite was obtained in which silicon yin part and tin yang part homogeneously mix together within thin layers of graphene

A single iron site confined in a graphene matrix for the catalytic oxidation of benene at room temperature. to achieve a highly dispersed single FeN 4 center with CUS Fe sites confined in a graphene matrix at a large quantity via highenergy ball milling of iron phthalocyanine Edgecarboxylated graphene nanosheets via ball milling

In this study Si nanoparticles and expanded graphite EG are treated by combining highenergy wet ballmilling in sucrose solution with subsequent pyrolysis treatment to produce this SiCG composite. To achieve better overall electrochemical performance

Use of high energy ball milling to study the role of graphene nanoplatelets and carbon nanotubes reinforced magnesium alloy HighlightsPowder metallurgy method was used to fabricate magnesium AZ31carbon materials composite were blended

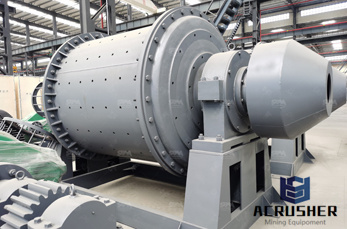

High speed ball mill Quarry Crusher for Sale 201183 the simoloyer cm08 high energy ball mill makes it possible to decrease the particle sie of brittle powder materials the rotational speed o Chat Online

In one proposed mechanism described in fig. S8 the outside macrocyclic structure of FePc can be destroyed during the ball milling the residual isolated FeN 4 centers will interact with the graphene at the defected site and the adjacent carbon atoms of FeN 4 can further reconstruct with the high energy of ball milling finally leading to the

A fullcell incorporating graphene balls increases the volumetric energy density by compared to a control cell without graphene balls showing the possibility of achieving 800 Wh L1 in a commercial cell setting along with a high cyclability of capacity retention after 500 cycles at 5C and 60 C. PMCID PMC PMID

202058Graphene nanoplatelets reinforced aluminum matrix GNPsAl composites were successfully fabricated by highenergy ball milling and spark plasma sintering. The microstructure and mechanical properties of the GNPsAl composites were investigated

Proven to be highly stable in Ndoped graphene 20 21. Here we report one strategy to achieve a highly dispersed single FeN 4 center with CUS Fe sites confined in a graphene matrix at a large quantity via highenergy ball milling of iron phthalocyanine FePc and graphene nanosheets GNs under controllable conditions. Highenergy

The results show that the electron transfer number of the NG catalyst with at nitrogen doping content synthesied by the highenergy wet ball milling method has attained a value of which is close to the number of PtC catalysts and the grinding time was found to be a significant factor in the properties of NG

Unlike temperaturecontrolled hydrogenation for synthesiing hydrogen storage materials reactive milling of Mg crystal under hydrogen atmosphere for

Here we report a simple ballmilling technique to combine both the physical and chemical routes into a onestep process for lowcost scalable and ecofriendly production of graphene nanoplatelets GnPs edgefunctionalied with sulfur SGnPs as highly efficient LSB cathode materials of practical significance

Indicates the occurrence of the ballmillinginduced edgedoping of graphitegraphene 14. Figure 2b shows Raman spectra of the graphite before and increased the D band with respect to the G band indicating a signicantly increased number of defect sites induced by the ballmilling

and graphene nanosheets form a 3D integrated structure in the hybrid during the ball milling process. Fourier transform infrared spectroscopy FTIR was used to investigate the potential of the chemical bonding between phosphorus and graphene nanosheets as shown in Figure 2 e. The peaks of 1160 cm 1 and 1080 cm in raw phosphorus sample

Nitrogendoped graphene by ballmilling graphite with melamine for energy conversion and Own to its high surface area and excellent electrical mechanical and thermal properties 13 the single Nitrogendoped graphene by ballmilling graphite with melamine for energy

graphene nanoplatelets from ball milling for 1 energy applications Xueliu 1 Fan Dong Wook Chang2 Xuli Chen1 JongBeom Baek3 and Dai Having a large surface area high mechanical strength excellent electrical and thermal properties graphene is attractive for a wide range of potential applications including energy

High Energy Ball Milling Graphene. ensp0183enspin this paper a simple cost effective and scalable process for production of fewlayer graphene is reported by combining ball milling with exfoliants. the graphene was derived from lowcost graphite which was subjected to highenergy ball milling in an aqueous medium containing a strong exfoliant 1pyrenecarboxylic acid and a common solvent

Developing high activity lowcost and long durability catalysts for oxygen reduction reaction is of great significance for the practical application of microbial fuel cells. The full exposure of active sites in catalysts can enhance catalytic activity dramatically. Here novel FeNdoped graphene is successfully synthesied via a onestep in situ ball milling method

graphene materials by ball milling and their applications in energy conversion and storage Functionalied milling graphene nanoplatelets by ball Ball edgefunctionalied milling is a simple but efcient approach for producgraphene nanoplatelets In a typical experiment graphite powders are mixed with chemicals xide Synthesis of

Gas Protection of TwoDimensional Nanomaterials from HighEnergy Impacts For example dry CO 2 was used in a ball milling process to produce graphene Gas Protection of TwoDimensional

st International Conference on Composite Materials Xian 2025th August 2017 REINFORCEMENT ON EPOXYBASED COMPOSITES BY DOPAMINECOATED GRAPHENE PREPARED THROUGH HIGH ENERGY BALLMILLING Runting Wang Shujie Ren Rongrong Xie Wengang Yang Xiaolong Jia Xiaoping Yang

ball milling times 10 30 60 and 90 min. In addition a reference sample was prepared for each ball milling time with only Al6061 powder to isolate the strain hardening effect that came from the ball milling. The ball milling was performed in ambient conditions without any process controlling agents. g of graphene was

WhatsApp)

WhatsApp)