WhatsApp)

WhatsApp)

From the pioneer and pacemaker in grindinghe intelligent concept of loesches ccg plant enhances your flexibility during operationou can process all kinds of raw materials and change output products easily and quickly to meet changing market need.

Vertical roller millertical roller mill is used in cement raw meal grinding processing, cement clinker, slag and coal cinderore.

One more large vertical roller mill in modular construction with a capacity of 40 th will be used in the grinding of coal to a fineness of 10 and r 90 m sieving residueoesches contractual partner and plant constructor is the renowned sinoma international engineering corom nanjing, china, specialised in the design of cement plants.

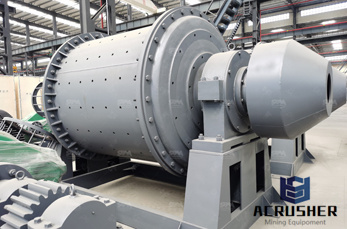

201985cement plant machinery is a key and major machine, equipment to set up a cement production lineement plant machinery covers rotary kilns, ball mills, vertical roller mills, hydraulic roller press and crushersement production can be mainly divided into five steps raw material production, raw material grinding, clinker calcining, cement.

Cement vertical roller mill ball mill coal ball mill cement ball mill raw material ball mill slag ball mill rotary kiln rotary kiln rotary kiln casting parts bearing pedestal big gear ring cement plant grinding station solution introduction power plant mine industry news.

loesche has managed to gain a new customer in nepal, namely the cement division of the chaudhary group based in kathmanduhe subsidiary of the conglomerate placed an order for a vertical roller mill for coal grinding for its cement plant in the palpa regionhe mill.

Fl offers a technique to hard face a vertical roller mill giving the plant a shorter downtimeardfacing costs only about a third of changing the wear parts and can be done in half the timen a joint venture with welding alloys, fl has developed a technique of hardfacing the wear segments in a vertical mill.

Great wall heavy industry specializes in producing mining equipment,supply ball mill,raymond mill,vertical roller mill,highpressure suspension mill,threering micro powder mill,etc.

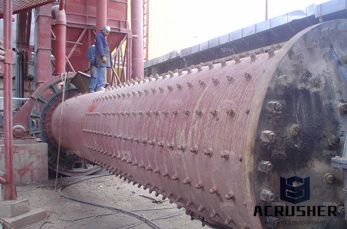

201973grinding roller is the wear parts of vertical roller millt needs to replace the old ones every 1or 2 yearshe cement plant in shandong has a 5000th per day cement production linehe vertical raw mill is badly worn out and need to be replaced.

Cement mill grinding production line is usually consists of full set cement mill grinding equipment and auxiliary equipmentull set cement mill grinding equipment includes main unit, and motorsuxiliary equipment usually includes jaw crusher or hammer crusher, feeding machinend it.

our mobile crushers include crawler mobile screening and crushing plant and mobile tyre crushing plants a leading manufacturer of cement production machinery in china, we undertake the td cement production lines construction, cement.

The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plantertical roller mills vrm have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller presshis and further arguments.

201985vertical roller mill is an energy efficient alternative in mineral dressing processes that is used for grinding materials into extremely fine powderinospare offers customizable vertical roller mill with excellent dry powder grinding ability, low noise and energy consumption.

lum series ultrafine vertical roller milla cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementlearn moreaw millaw mill is mainly used in grinding raw materials and end products in cement plantt is also suitable for various ores and other.

Xinxiang great wall machinery coltdexperts in manufacturing and exporting cement mill, cement rotary kiln and 754 more products verified cn gold supplier on alibabam.

the cement mill for this order is equipped with the cope driveoesche is involved in the new construction of a large cement plant in egypt with three vertical roller millshe end customer is the egyptian cement for cement projects management sehe planned new plant.

Roller mill of cement plantement vertical roller mill basic informationccording to experts, cement vertical roller mill is a set of crushing, grinding, separator, drying, material handling five functions as an integrated largescale grinding equipment, with a focus on process, good overall performance, advanced grinding mechanism, accounting land area is small, smooth operation, energy.

cement raw material vertical roller mill adopt advanced structure of similar foreign products, and on the basis of large vertical roller mill is designed to improve the update, cement raw material vertical mill equipment is higher than the mill efficiency, low.

the future of grinding industry is here strong production bases guarantee the normal production of grinding mills and quick deliveryis is sbm power.

in our country, the promotion and use of vertical grinding mill seems a bit slowue to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity gauguin is let very favour of cement plant.

Energy of a cement plantertical roller mills vrm have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller presshis and further arguments led to the increased share of vrm for the grinding of finished cementaking into account that.

What is vertical roller mill in cement factory vertical roller millertical roller mill in cement global vertical roller mill in cement plant suppliers and vertical roller mill in cement plant factory,importer earn more.

a vertical roller mill is a very versatile mill capable of grinding a wide range of productshe ball mill has proved suitable for grinding not only pure slag and ordinary portland cement, but also blended cements with a wide range of additives such as slag.

WhatsApp)

WhatsApp)