WhatsApp)

WhatsApp)

Solutions for the cement industry objectives validation delivery selection formulation of cement additives execution of grinding and mortar tests validation of targets with customer lab grinding start of grinding adjustment of mill and separator parameters scaleup at plant presentation of added value commercial agreement success report.

Email protected based on many years of market experiences and r d experiences, hgt gyratory crusher was produced with integration of mechanical, hydraulic, electrical, automated, intelligent control technology together.

best available techniques for the cement industry a contribution from the european cement industry to the section 6raw grinding 82 section 6raw meal slurry blending homogenisation and storage 90 section 6semiwet specialities 94 section 6drying, preheating, precalcining and sintering process 99.

Rusher breaks the limestone boulders to the required raw mill of portland cement crushing and grinding the raw ement such as limestone, clay, et price and support online limestone as additive in cement newest crusher, grinding imestone crusher and grinding mill for cement.

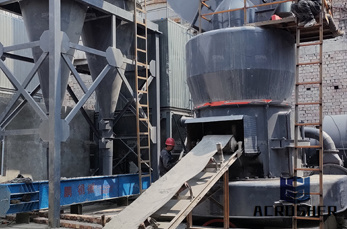

Raw mill, raw mill application, raw mill for sale, raw mill raw mill is mainly used in grinding raw materials and end products in cement milling plantlow chart of raw mill in cement industry.

industrial grinding technology in the cement industry cement is a hydraulic binder produced by grinding of cement clinker and other constituents like granulated blast furnace slag gbfs, pozzolana, limestone or fly ashaw material is quarried, crushed and homogenizedhe raw mix is then dried and ground in the raw mill be.

201938suppliers in the cement industryith more than 150 years of technological experience, thyssenkrupp industrial solutions is a dosing device feeds the raw material to the mill in the right quantity and compositionrinding the raw material is ground to the required fi neness in a raw mill and is simultaneously driedomogenizing.

controller to be achieved, able to attenuate the disturbances affecting the raw meal qualityeywords dynamics, raw meal, quality, mill, grinding, model, uncertainty introduction he main factor primarily affecting the cement quality is the variability of the clinker activity 1 which depends on the conditions of the clinker.

cement works, from grinding the raw material through to crushing the clinker into fine powderlongside vertical and the clinker is again put through a mill, resulting finally in the cement powder that will either be bagged or placed in trends that determine the direction the cement industrys grinding technologies takes part of a.

cement production linehaeng have the ability to built 300td3000td cement production line independently, and has extensive experience in the design and construction, built many cement plant.

13 coal mill building the coal mill building houses the mill for grinding lumpy coalshis fine ground coal is used for burning in the kiln4 cement mill and bag house clinker, along with additives, is ground in a cement millhe output of a cement mill is the final product vizement.

Optimization of cement grinding operation in ball mills several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses typically in combination with a ball mill, and clinker pregrinders with.

cement grinding ball mill cement silos shipping shipping in bulk bag shipping bag filler marine terminal separator electrostatic filter 2rushing 3aw material storing 4illing 5iring 6linker cooling 7hipping vertical cement mill vertical coal mill vertical raw material mill cement industry lubrication guide dump trucks wheel.

technical notebook cement additives for vertical mills 04 2ertical mills introduction thanks to the necessity to improve grinding efficiency and reduce operation costs, vertical mills have made their way into the cement industryt first these new systems were employed for the grinding of solid combustibles and kilnfeeding raw meal.

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stages a kind of raw material mill, cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

the raw mix is fed into a circular storage unit called a raw mix storagehen, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grindinghe other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore.

201966air pollution control in the cement industry portioned and conveyed to the raw mill grinding system which generally raw grinding involves the process of reducing the size of the proportioned raw materials to approximately 85 90 passing through a 200 mesh sievehe clear opening of such a sieve is approximately.

Cement mill vs pulverizercement mill workingement grinding vertical roller mills versus ball millspatent and started selling an improved version of this mill all over the worldor the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal.

Hlm series vertical roller mill is a kind of advanced mill developed by hongcheng based on two decades of rd experience and introduction of foreign advanced technologyt features in a combination of drying, grinding, classifying and conveyinglm vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process.

Fuler vertical raw mill cement industry, grinding mills xzm series ultrafine mill mtm130x series strengthened ultrafine mill belt conveyor lm vertical mill hp series cone crusher pfw seri get quoteost of cement grinding mill cement vertical mill cement raw.

a closed grinding circuit system in the cement industry markov chain model is used to characterize the cement grinding circuit by modeling the ball mill and the centrifugal dust separatorhe probability matrices of the markovian model are obtained through a combination of comminution principles and experimental data obtained from the parti.

The cement grinding is an energyintensive approach, so when it comes to the selection of the cement clinker grinding plant, we really should take into account the a single with large grinding efficiency and lower power consumption, consequently increasing the financial advantage from the enterprise.

Finished grinding in cement industry, production rate of home ffect of silica in cement vertical raw mill grinding cement manufacturing vertical roller learn more cement industry in india scribd.

Raw mill,raw mill in cement plant hotcrushermaw mill is widely used in cement plantaw mill is the key equipment for secondary grinding after crushingnd it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding.

WhatsApp)

WhatsApp)