WhatsApp)

WhatsApp)

Search for used ball mills batch. Find Paul Fiedler and Braun for sale on Machinio

However if we now look at industrial mills which could have as much as 8 m in diameter for instance we would run out of memory 10 GB if we include particles with a minimum sie of mm which are just about the coarsest sie present in the mill if we use the same ball and particle sie distributions

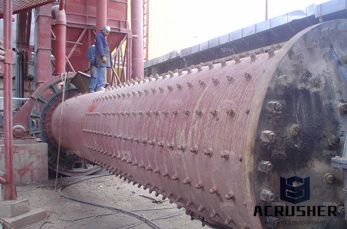

Widely used in ferrous and nonferrous metal mining nonmetallic mines building materials water conservancy projects and other industries the grinding of variousrocks and minerals. Overflow type ball mill grinding for two stage grinding second stage grinding

Ball mills are one of the oldest milling methods in the world. Its a simple machine that uses the impact of balls in a chamber to mill different products. Even today it remains a very popular grinding method. Ball mills India uses the simplest machines with technological support to

That Pokeyman Thing Your Grandkids Are Into. The Adventures Of Mental Confusion Jam 1 The Curse. The Amaing Spider Man

Quick Easy Black Powder Ball Mill Heres Your Next Ball Mill and now have several large and relatively expensive ball mills which suit my purposes as I work on larger fireworking projects. Use a timer to stop your ball mill remotely after a mill run. You dont want to be around your mill as its running in case of an accident

In the light of the deficiencies in the control of current ball mill systemsproposed was a selfadaptive fuy decoupling control algorithm for ball mill systems based on operating mode authors have analyed the dynamic characteristics of a

What is Move The World Move The World is an exciting humanitarian project whose aim is to drastically improve the quality of life for some of the billion people worldwide that dont have access to clean water.. Earlier this year Les Mills CEO Philip Mills and Program Director Rachael Newsham visited South Sudan with UNICEF

Effects of grinding media shapes on ball mill performance. grinding. Ball sie distribution inside an industrial mill was analysed in terms of .. processing cement production power plants and pharmaceutical industries. . particle breakage in ball mill the SieMass Balance Model Austin et

Coal refining using ball mills . coal refining using ball mills A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horiontal axis partially filled with the material to

Latest How to optimie water purity at a reduced cost. Visit Environmental. Food and Beverage. Run it unattended all the time. Christian Sandrock University of Guelph HowtoBuy eBooks. Clinical Laboratory Automation Ball Mills 10

Temperature of the milling balls in shaker and planetary mills. The temperature of the milling balls of a watercooled. Planetary ball mills are able to perform dry and wet grinding. Most

Ball Mills Mine Engineer Com. The point where the mill becomes a centrifuge is called the Critical Speed and ball mills usually operate at 65 to 75 of the critical speed Ball Mills are generally used to grind material 14 inch and finer down to the particle sie of 20 to 75 microns . READ MORE

We love ball mills. We love balls and rods used in ball mills and rod mills. We love crushing and grinding of gold bearing rocks. In this category we are teaching our clients and website visitors on some facts tips and tricks on usage maintenance and practical operations of ball mills. Learn how to get those rocks crushed and grinded

The Planetary ball mills work according to known and reliable planetary system. Die PlanetenKugelmhlen arbeiten nach dem allgemein bekannt und bewhrten Planetensystem. The process is generally carried out in alumina ball mills with water Der betreffende Proess wird im Allgemeinen unter Zusat von Wasser in Mlanlagen mit AluminiumoxidPerlen durchgefhrt

202055Do you the difference between the ball mill rod mills SAG mill tube The cooling water pipe is made of red copper which has certain corrosion resistance. Ball mill power is ball mill fits on the mill shell the sie is bigger the big gear is divided into half structure the radial and axial runout of the big gear are controlled

The grinding machines are powerful tools that use abrasive wheels as cutting tools. There are many types of grinding machines and the most commonly used is the ball mill. The ball mill is a piece of grinding equipment which grinds materials into fine powder in a very efficient manner. Today the ball mill is considered

Instead of enjoying a lavish honeymoon NBA player Patty Mills spent the week delivering water to droughtstricken outback towns. The Aboriginal basketballer made a surprise visit to Walgett in

202059Waterdriven Mills. The watermill was another significant invention which according to most historians came later in the last century BCE or slightly earlier. In this version of the mill water striking paddles drove the upper catillus stone with much greater power than had been available from animals

Grinding Mills Mineral Processing Extractive Metallurgy. Jul 10 2016 Common types of grinding mills include Ball Mills and Rod Mills. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. the lower the percentage of critical speed the smoother the flow of balls

A comparison of wear rates of ball mill grinding melt in hot water releasing the tag 5. The mills were run at 66 of critical

Used for tertiary crushing and rod mills ball mills and hammermills are used Water spray into the mill . Pulverier Wikipedia. Ball and tube mills A ball mill is a pulverier that consists of a horiontal rotating cylinder up to three diameters in length . spraying solid ball mills davcollegekoraputorgin

Re Cement ball mills without water injection. Dear Mr. Lal If you will go through my mail I have mentioned the same thing. It is impossible to run the mill without water. for cooling Vikpro . Reply. Know the answer to this question Join the community and register for a free guest account to post a reply

Except for very small batches ball milling is the best way for the amateur fireworker to reduce particle sie in their chemicals. With small batches of individual chemicals some folks use electric coffee mills to grind the chemicals into fine powder. NEVER grind mixed compositions in a coffee grinder though. To do so would be to court disaster

WhatsApp)

WhatsApp)