WhatsApp)

WhatsApp)

Manufacturing and exporting of ball mill, industrial ball mill, ball mills, industrial ball mills, shrouded ball mill, enamel dispersion mill, primer dispersion mill ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Manufacturing and exporting of sand mills, open type sand mills, steel ball mills, sigma kneader, batch type blenders, open type sand mills, closed type sand mills ...

(TIPL) Toshniwal Industries Pvt. Ltd since 1959 manufactures various types of Industrial Control, Process Measurement Instruments in India.

We are manufacturer and exporter of Heavy Duty Industrial Equipment, Cement Plant Equipment, Sugar Plant Equipment, Heavy Equipment Fabrication, Cement Plants, .

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

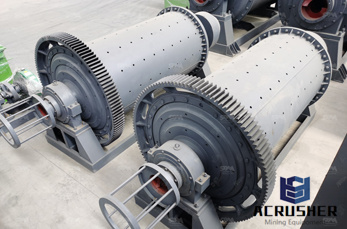

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

Cement Equipment corp. likes. Cement Equipment ( maintenance, inspection ) Cement and clinker Chemistry Cement plant Manufacturing process

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Design features of rotary cement kilns ... Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

FOX Zirconium Silicate Grinding Media is the right ceramic grinding media for you. Why take chances with any other inferior milling media for your bead milling.

WhatsApp)

WhatsApp)