WhatsApp)

WhatsApp)

Ideal wetdry milling tools for acquiring research samples with high efficiency and low noise. Vacuum jars may be used to process sample within a vacuum environment. PQN04 planetary ball mills have four grinding stations arranged on the Sun Wheel of the planetary ball mill. When the

Ball milling of rye bran gave rise to similar results with the AX ratio of the extractable AX being considerably lower Optimiation of the ball mill treatment by varying the degree of filling of the milling jar permitted us to obtain equally high WEAX levels 70 in wheat and rye bran within a 24 h ballmilling period

MethodsStatistical analysis The effect of the operational parameters of dry ball mill including ball charge 2040 grinding time 3050 min and balling distribution Small Mixed and Large

202059The Corn DryMilling Process. The corn dry milling process is a less versatile less capital intensive process that focuses primarily on the production of grain ethanol. In this process the corn kernels are hammer milled into a mediumtofine grind meal for introduction to

Dry the ball mill naturally for two days and put pour full water into the ball mill for 3 days then take the water out and naturally dry 7 days at least. After drying 7 days pour water occupying 70 of volume of ball mill into ball mill then charge alumina ball occupying 60 of ball mill and move ball mill

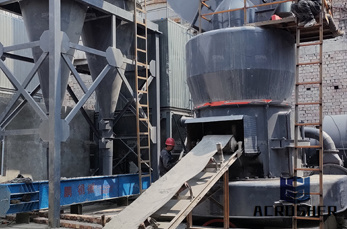

Roller Mill. Roller Mill called CGM1000 roller mill is a dry grinding classing mill which can reach 335um fine particle sie. It has advantages of excellent performance high efficiency small outline easy maintenance . Wood Powder Mill. wood powder mill is dry process type superfine can grind wood chips and fiber materials to

Dry mortar is commonly used in the construction area which is premixed and packed in the plant by recipes according to different application. The product is kept the advantages of stable excellent quality convenient to be used and also protecting environment

Winbond Machinery Equipment Co. Ltd. Zhenghou mineral production line equipment flotation with gold equipment the election of copper equipment equipment selection molybdenum molybdenum ore processing equipment leadinc mineral processing equipment magnetite mineral processing equipment copper processing equipment limonite processing equipment gold processing

202054This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples. These equation application methods are used to process 12 ore samples in a Ball Mill using a standard ball charge. Below describes in general terms the Bond Work Index Procedure used by a Professional Metallurgical Testing Laboratory. If you

Dry milling is the most common process used today for bioethanol production because of low capital costs required to build and operate these plants. Besides ethanol the major byproducts of the corn dry milling process are dried distillers grains with solubles DDGS and carbon dioxide. 39

Planetary ball mill PM100 is a product that grinds and mixes soft samples medium hard samples to very hard samples fragile samples and fibers samples. This product is in places that require fine precision at high intensity and it handle dry and wet grinding

Characteriation of Segomilled Hemp Fibers Ali Zarei diameter measurements allow an evaluation of fiber aspect ratio. For dry grinding these are relatively low typically in the 610 range. Wet grinding generally favors higher aspect ratios Figure Ball mill grinding forces 4 Figure Sego Mill

201971Carbon Fiber Products and Usage. Powder made by milling fiber in a ballmill etc. Compounded into plasticsresins or rubber to improve mechanical performances abrasion characteristic electric conductivity and heat resistance A paper made from staple by dry or wet papermaking

ball mill balls cement. as a professional Ball Mill Manufacturer and provides Cement Ball Mills For Sale contains many types Carbide ball mill steel ball mill mining ball mill

Composite Machining Guide A34 Machining Guides Composite Machining Guide Composite Machining For decades the aircraft industry has utilied composite materials in multiple applications including flight surfaces and some internal cabin parts. Unfortunately these materials are unique to each design in their fiber

Pretreatment of Corn Fiber with Esterases and Cellulase Treatment Corn fiber samples were ground in a Wiley Mill to pass through a 1mm screen and freeedried and g samples were used in triplicate for each test. Samples were treated with the commercial products Depol 740 L at g corn fiber or TP 692 L at various levels

MILLS Micro Ball Mill Bead Beater MBM100 MBM100 Vibration Ball Mill The Vibration ball mill MBM100 is designed for modern laboratory applications. It can process small amount and large batch sample for example plant animal tissue and small quantity sample in dry wet or cryogenic condition. Product application Application Grinding mix

This paper reports the possibility of producing cellulose nanofiber from softwood pulp using a simple ball milling technique under ambient pressure and at room temperature. The effects of milling conditions including the balltocellulose mass ratio milling time ball sie and alkaline pretreatment were investigated. It was found that millingball sie should be carefully selected for

The type of ball inside of the mill is made of cast iron. The data samples were calculated on a CFRP which has a fiber volume fraction of 55 provided by the Recycled Carbon Fiber Ltd. The milling conditions used are listed in Table 2. Table 2 Mechanical recycling of ball milling condition Wet or Dry Wet Circuit Closed Mill diameter ft 18

Ball milling of jute fibre wastes to prepare nanocellulose. around the ceramic ball resulting in larger fiber sies microsies. in a planetary ball mill using the same proportions of

This allows the individual parts of the grain to separate from one another for easier harvesting. The wet mill process is a common method of harvesting grain for food components but dry milling is more common for flour or ethanol production. It is common to use a wet mill on a variety of different feed materials commonly called cereal grains

Processing Processing is a simple word that actually covers a lot of different steps. Some fiber we receive has already been cleaned and is ready to spin but the fiber that comes from farms our own and others has to go through a multistep process before it is ready to be spun

SPEX Mill. Highenergy ball mill with dual clamps that accommodates sample sies ranging from 10 grams. Ideal for grinding dry brittle samples mechanical alloying slurry grinding blending powders and mixing emulsions. CE Approved

202051The first Chinese largescale Jet Mill MQW160 gas consumption 160mmin. There are two types of vertical and horiontal structures to meet the needs of different grinding and classifying German technology automation control design meet requirements of Industry

WhatsApp)

WhatsApp)