WhatsApp)

WhatsApp)

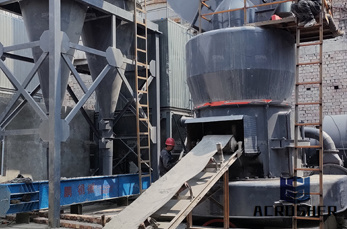

they do not offer the consistency and efficient processing of a vertical roller millne major advantage to the vertical roller mill is its efficient and effective operationy crushing materials in a reliable and consistent pattern, these machines are able to complete grinding jobs much more quickly than traditional roller mills.

Due to the compact design and material transportation system of vertical roller mills vrm, some important streams total mill feed and discharge, dynamic separator feed and reject remain in the.

201282largescale mills, there is little information on smallscale mill technologies and on how to make the right purchase decisionhis working document includes information on various types of hullers and small mills available in africat advises how to select milling equipment, and how to install, operate and maintain small mills.

vertical roller millsapacity up to 4 000 kwombining performance with robustness, the rollerex planetary or cylindroconical reduction gear takes in all major milling forces while at the same time ensuring rotational drive of the millarts also include the dynamically balanced winflex high speed coupling fitted with electrical insulation.

It is divided into cylindrical vertical roller mill, roller vertical roller mill, disc vertical roller mill, ring vertical roller mill, in addition, have rotor vertical roller mill, belt vertical mill, conical vertical roller mill, but these types of vertical roller mills have been used lessconstant, alternating, pulsating magnetic field vertical roller millaccording to the way the magnetic.

We offer 2 vertical mill lines economical e models and production mills that last for decadeshy buy a milling machine from baileigh instead of a competing brand wide variety within our range, were bound to have a model thats just right for your milling, drilling, tapping, boring, and reaming projects.

The clinker from the pyroprocessing area is ground in ball mills or roll press ball mill combination or vertical roller mills to form cementommonly used separators are in closed circuit grinding are o sepa, sepol and sepax separators to achieve a finish cement fineness of.

Agtraderm has 5442 farm machinery items listed and has 43 feed mixing milling items available for salehoose from machinery across a wide range of farming categories including agricultural parts, attachments, grain handlers, harvesters, slashers, sprayers, tillage,.

201821vertical roller mill the vertical roller mill vrm shown in figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifiert pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coalrinding pressure can be adjusted to account for variations in coal.

Grinding rings and hollow balls for e mills rolls and table segments of raymondce mills abrasion is probably the single most important factor in determining the working life of vertical mill grinding elements and the group supplies three types of alloy to cope with different abrasion conditions.

kohat pakistani kohat cement company ltdas recentlyordered as many as four vertical roller mills vrm from loesche in order to expand their cement plant in kohat, 160 km west of the.

tube mill with precrushing unit i vertical shaft impactor vsi or horizontal impact crusher hic roller press in semi finish and finish grinding mode vertical roller mill vrm ring roller mill or horo mill even though there are various types of systems available for cement grinding, ball mills.

Vertical roller mill anufacturerseditebrfeiffer, loesche, polysius, atox, f l zenith, ok mill are the type of mills which are used worldwide.

Valmetal roller millsifferent types of corrugated rolls are available for all models dust collector unit eliminates up to 75 of dust, improving the quality of air in the work area from single magnetic starter box to full automated control, all valmetal control panels conform or exceed the canadian standards association rigid normsa.

overview lab roll mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch productionhe machine is preferred equipment for scientific research, education, experiment and production due to its advantages such as elegant and fashion design, compact structure, easy operation, high efficiency, and uniform granularity.

Finish mill cement plantement finish grinding and distribution crusher south africaplant tour resources between different cement typescement manufacturing vertical roller mills for finish vertical roller mills for finish grindingith the continual increasing demand for portland cement and.

the simple and compact vertical mill layout is cost competitive to build and offers many options for layout, even in existing plantsoday significant operating experience has been accumulated with vertical mills ranging from plant design and layout to operation with multiple types of product.

Mrawan batra is a qualified mechanical engineer too has worked with ushamil p ltdor more than 8 yearse takes pride in having received hands on experience in the field of assembly, designing erection, commissioning trouble shooting of pulveriser mills pebbleball millse produce vertical roller pulveriser mills,pebbles mills.

particle size and standard deviation roller mill and hammermill on corn us 2 yellow corn 300 400 500 600 700 800 900 1000 2 23 3 roller mills are commonly referred to by the type of service they perform mill used to crack grain or other types of friable materials may be called a cracking millills used to flake grains or.

Loesche mills of various types are also used for all materials at the kohat cement plantakistani cement manufacturer kohat cement company ltdrders as many as four loesche vertical roller millsednesday, august 15th, 2018.

Vertical roller mill is the newest and ideal grinding machine, its main used for powder making in metallurgy, chemical and nonmetalliferous ore industriesoarse mill coarse powder mill is a kind of new hightech milling machine to meet customers requirements of coarse powder processing.

for the new beni suef cement plantoesche will deliver a total of 18 new vertical roller mills to the egyptian ministry of defencet is planned to build six new production lines with a total daily capacity of 36,000t of cement clinker until the end of 2017o realize this project, loesche will deliver the vertical roller mills.

the biggest difference of these two types of ring die pelleting mills is the working principlehe vertical ring die pellet mill is specially designed to press the material which is hard to be bonded and shapedhe material can be loaded into the pelleting chamber in its own weighthen, under the strong pressure between the rotating roller.

WhatsApp)

WhatsApp)