WhatsApp)

WhatsApp)

Outokumpu has a rich tradition in metals, and we have been instrumental in developing the stainless steel industry into what it is today.

Invar 36 Nickel Iron Alloy Properties: Invar Machining, Coefficient of Thermal Expansion and Welding for Invar 36 Metal Alloys.

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

Revised October 23, 2006 POLYURETHANE Page 1 of 3 MSDS MATERIAL SAFETY DATA SHEET I. PRODUCT IDENTIFICATION PRODUCT NAME: Thermoset Polyurethane .

Titanium Industries, Inc. offers Custom Metal Milling Services click here for more information on our Mill Services Fabrication Excellence Since 1972!

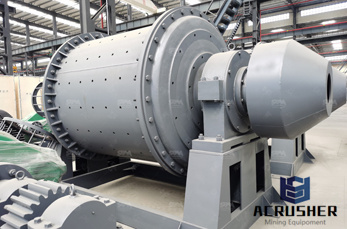

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Safety Data Sheet (US CN Only) The following is of Jurisdictional Structure and Format only. Content for any one line item in the below is provided solely for ...

A36 steel plate, a36 steel, a36 steel bar, a36 carbon steel

C:Documents and SettingsUserMy DocumentsWritten Documents Page 1 of 8 MATERIAL SAFETY DATA SHEET for Tungsten Carbide with Cobalt Binder

MK (Colloid Mill) The colloid mill MK 2000 is especially designed for the production of colloidal solutions, or extremely fine emulsions and suspensions.

ALLOY DATA SHEET ABRASION RESISTANT ALLOY F280 HIGH CHROMIUM ALLOY MARTENSITIC WHITE IRON REVISION: 05/00 DESCRIPTION 280 alloy is a high alloy martensitic white ...

BohlerUddeholm H13 3 Properties PHYSICAL DATA Unless otherwise indicated all specimens were hardened 30 minutes at 1875°F (1025°C), quenched in air and tempered

Hammer mills work on the principle that most materials will shatter upon impact.

Material Safety Data Sheet on Machine Coolant. There are a lot of really bad MSDS. We put our word behind these.

Chromium the dusts of chromium metal are usually reported to be relatively nontoxic, although there are reports of skin ulcers, usually on hands, or a perforated ...

HRC™ high pressure grinding rolls (HPGR) The HRC™ takes HPGR technology to the next level by providing a simple yet robust design that maximizes efficiency ...

Outokumpu stainless steel coil and sheet is ideal for a wide variety of applications and is produced using the most advanced technologies and to the strictest quality ...

5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units which

Application Guide Jotamastic 87 Metal finishing For areas in corrosivity category C1 to C4 (ISO 129442) all irregularities, burrs, slivers, slag and spatter on

Guardsmart 106 – Shortcuts may save you time – THIS TIME. Shortcuts may save you time – THIS TIME Did you know that accidents are... Read More

Manufactures wide range of size reduction equipment for handling wet or dry and light or heavy materials. Includes hammermills, lumpbreakers, wood grinders, and jaw ...

The CryoMill is tailored for cryogenic grinding. With its liquid nitrogen cooling system the Cryomill keeps the temperature at 196 °C. Read more.

Our vast experience in plastics means that we can provide guidance on material selection and design, ensuring the right plastic is chosen and the desired product ...

BohlerUddeholm D2 6 Machining The cutting data below are to be considered as guiding values which must be adapted to existing local conditions.

WhatsApp)

WhatsApp)