WhatsApp)

WhatsApp)

Pearson Coal Petrography » Vitrinite Reflectance Vitrinite Reflectance. The reflectance of vitrinite remains the most definitive measure of coal rank, ... and to confirm proportions of components in a blend. » Learn More Coal Power ...

Mills and Components 5 In hard coal boiler units, gravimetric coal feeders are used to discharge the raw coal from the bunker. In lignite plants, dragchain conveyors together with belt conveyors are used to discharge the raw coal from ...

coal pulverizer wear parts Coalfired power plant wear parts coal pulverizer wear parts... High chrome, medium chrome and low chrome alloy Grinding Balls are available in following diameters ... » Learn More Wear components » ...

wear components for coal grinding wear components for coal grinding XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and ...

wear components for coal grinding wear components for coal grinding Diamond Gem and Industrial Uses . The unique properties of diamond make it suitable for many different uses including: gemstones, cutting tools, heat ...

134 P. OrtegaCubillos et. al; Revista Facultad de Ingeniería, No. 76, pp. 134142, 2015 Wear resistance of high chromium white cast iron for coal grinding rolls Desgaste de fundiciones de hierros blancos de alto cromo usados en ...

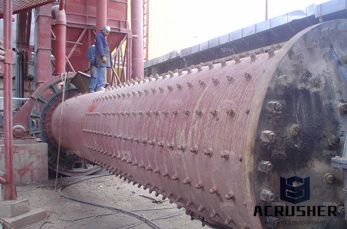

Regeneration of Grinding Components in Roller Mills and Reducing Wear in Other Areas Introduction Roller mills have gained a firm footing in many industrial branches for the size reduction of bulk materials. Roller mills are also ...

Grinding Elements Coal + garmentmachines Grinding Elements Coal. grinding elements in coal mining south africa. Discrete element method modelling of liner wear ... grinding elements coal + ZCRUSHER grinding elements in coal ...

E Type Coal Grinding Mill Life Type E E Type Coal Grinding Mill Life Type E E and EL Pulverizer Modifications The Babcock Wilcox Company and reliability of Etype pulverizers. The ELtype pulverizer is also much less prone ...

Coal Crusher Wear Columbia Steel Coal Fired Power Plant Wear Parts Columbia Steel Casting Co. manufactures quality replacement wear parts for coal fired power plants, including: tires, grinding ring segments, boltthrough ...

Regeneration of Grinding Components in Roller Mills, and Reducing Wear in Other Areas Introduction, grinding coal and in cement plants for, 1: Grinding rollers in roller mills are subject to considerable wear; Contact 2014 MPS ...

This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components. This assists in the evaluation of mills and coals for particular duties and ...

2017/08/13· This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components. This assists in the evaluation of mills and coals for particular ...

wear components for coal grinding Crusher Machine Grinding elements take the wear and tear of coal Magotteaux VRM grinding elements have been implemented on all types of coal pulverisation from brown Get Price Online

(under pressure) between the grinding elements by means of centrifugal force imparted by the rotating table or by a rotating pendular shaft, is being crushed against itself. As such the primary wear component in the crushing zone is ...

wear components for coal grinding Feldspar . wear components for coal grinding XSM excellent mining crushing machinery products or production line design, ... ... components of a coal pulverizer – Grinding Mill . » components ...

wear components for coal grinding XSM excellent Iron Ore; Grinding information on the wear rate of the grinding . Component wear in vertical spindle mills grinding coal ... Wear of the these components is the ... 1986) showed a ...

wear components for coal grinding Mining equipment, parts, tools and services Mining helps the global mining industry excavate, transport and process ore, safely and productively. Part of the Group. Get Price Online » Particle ...

Lining for grinding machine parts [0005] Over time, the components of the mill liner wear and require mill grinding machine concrete grinding disc low energy Get Price Online coal grinding mill components coal grinding mill ...

wear components for coal grinding coal processing plant Quarrying Crushers are mainly used to make building stone materials and manufacturered sand. CGM supplies complete crushing and screening plant for our clients all ...

KALPRAXIS Regeneration of Grinding Components in Roller Mills ... grinding coal and in cement plants for raw material ... 1: Grinding rollers in roller mills are subject to considerable wear; ... utilize ABRESIST fused cast basalt. Get ...

Particle Impact Erosion and Abrasion Wear – Predictive Methods and Remedial Measures Report No. COAL R241 DTI/Pub URN 04/701 March 2004 ... EXECUTIVE SUMMARY Objectives The overall objectives of the project can be ...

enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates. Further pulverization is achieved as the smaller coal particles are ground through attrition against each other and the ...

2013/02/01· Wear mechanisms in a coal pulveriser Compression, abrasion and impact are the three wear mechanisms that act upon the grinding elements and the pulveriser internals. Compression is a wear component that results ...

WhatsApp)

WhatsApp)