WhatsApp)

WhatsApp)

200682envirofriendly hydrogen generation from steel millscale via metalsteam reforming abdulmajeed azad sathees kesavan the university of toledo bulletin of science, technology society vol6, no, august 2006, 305313.

Ukrexport also has direct access to producers of couple of specialties in metallurgic industry, either produced in ukraine or shipped by logistics of ukraine the great silk road 1 white, grey, ductile pig iron both giving extra low mn, s, p and.

201936of added metallic iron or the metallic iron reduced from mill scale or magnetite, which can decrease the activity of chromium by having chromium dissolve in the iron n situhe results from the induction furnace experiments show that the steel can be directly alloyed with.

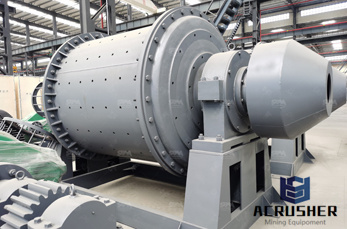

in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the mineralsn the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

metallic iron such as directreduced iron dri or hot metal can also be used in the eaf routehe main coproducts produced during iron and crude steel production are slags 90 by mass, dusts and sludgesrocess gases, for example, from the coke oven, bf or bof are also important coproductsowever, this fact sheet will mainly focus.

Developed by midrex technologies, inca wholly owned subsidiary of kobe steel, the midrex process utilizes natural gas to make direct reduced irons the worlds leading direct reduction process, it is used in over 70 plants worldwide, particularly in the middle east.

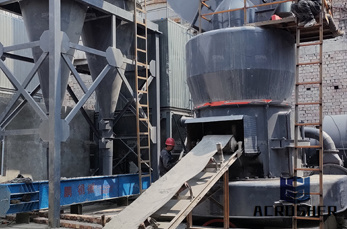

Raymond mill is our company based on years of experience in r d and production of milling machine, granulated blast furnace slag special products, through multi unit cooperation professional team of painstaking research, the calculation, the the.

evolution study of crystal parameter for ron powder subjected to mechanical milling oan taut, george arghirechnical university of clujnapoca ioantaut2002yoom abstractn a planetary mill with balls of high energy, the experiences of milling on different time interval of iron powder.

Iron ore pellets and pelletizing processesatyendra february 23, 2013 6 comments grate kiln process, iron ore fines, iron ore pellets, pelletization processes, straight kiln process, iron ore pellets and pelletizing processes pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then.

Aerodynamic mill design for increased airflow and cooling y mainline vacuum pipe to the mills allows for equal vacuum draw at both mills, thus increasing the airflow to the mill chambershis allows increased material flow capabilities in the mill chambers.

safe carriage of iron ore other iron concentrates in bulk iron ore is used for the production of metallic iron in steelmakinglthough some 45 countries export natural iron ore resources, seven countries provide 75 of the total exportedhe two largest exporters are brazil and australia, with about 33 of total world exports each.

Mill heads copper ore mill tails molybdenum oxide concentrate powder form bauxite, australiandarling range rutile ore iron ore canada iron oxide, reduced iron ore, labrador iron ore nimba phosphate rock, western bauxite, surinam bauxite, powder form phosphate rocks and bauxites srm 69b 120c 600 694 696 697 698 description bauxite.

The relations between the milling periods with the iron mill scale particle size have been studiedron mill scale has been chosen for this research due to the nature of itself, as a byproductrom this research, the average optimum size for the final iron mill scale particle size intended to produce is at 300 maw iron mill scale received from the industries was in the form of chip.

The companies under kymera international have a long history and have been producing metal powders for over 100 yearshe group has manufacturing plants in seven countries and produces a wide array of materials including aluminum and aluminum alloys, copper and copper alloys, copper oxide, lead, magnesium, plain bearing alloys, silver coated, tin, zinc and various specialty alloys in a wide.

Cast iron powders, prepared by pulverizing turning, milling and grinding chips separately in a bail mill, compacting characteristics of cast iron powder prepared from machining swarf sharma c 1986 compacting characteristics of cast iron powder prepared from machining swarfn davies b eds proceedings of the twentysixth.

grinding millsm grinding mills vary from coarse grinding, medium grinding to micro fine grindinginding millgrinder millis widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials processinge materials include line, calcite, barite, coal, gypsum, mica and bentonite powder.

674b xray powder diffraction, intensity set quant analysis 10 g powder 675 line position, mica xrd 7g 691 iron oxide, reduced 100 g 692 iron ore, labrador 100 g 693 iron ore, nimba 100 g 694 phosphate rock, western 90 g 695 70 g 696 60 g.

iron powder having the abovementioned particle size distribution is prepared by reducing the wateratomized iron powder or iron oxide powder such as mill scales, disintegrating the reduced iron powder, and then classifying the disintegrated powderreferably, the steps from the reduction to the classification are repeated several times.

vale is the worlds biggest producer of iron ore and pellets, raw materials essential to the manufacture of steelron ore is found in nature in the form of rocks, mixed with other elementsy means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies.

Mill scale is waste obtained from iron industryt is generally produced during continuous casting soaking, reheating and rolling operationshis is relatively pure iron oxide with little contaminationt is a magnetic material consisting of ir.

201123iron ore processing for the blast furnace courtesy of the national steel pellet company the following describes operations at the national steel pellet company, an iron ore mining and processing facility located on the mesabi iron range of minnesotareating steel from lowgrade iron ore requires a long process of mining, crushing,.

pure iron is not readily available since it easily oxidises in the presence of air and moisturehe iron industry reduces iron oxides to obtain pure iron, i metallic ironteel is an alloy based on iron and carbon, with carbon concentration ranging from 0to 2 in weightigh carbon content results in higher hardness, tensile.

iron ore powder price select 2019 high quality iron ore powder price products in best price from certified chinese electrolytic iron powder manufacturers, iron pyrite powder suppliers, wholesalers and factory on madeinchinam.

Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etcaterial can be pulverized into 80400mesh with this mill.

WhatsApp)

WhatsApp)