WhatsApp)

WhatsApp)

cement grinding optimisation CiteSeerX increasing at about 1% per annum. The electrical energy consumed in cement production is approximately 110 kWh/tonne, .. There are efficiency factors for dry grinding, open circuit ball ...

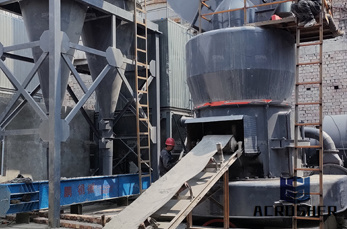

Vertical roller mill Wikipedia, the free encyclopedia A vertical roller mill has thus been developed and installed, enabling a reduction in power consumption and improved milling efficiency. (2) Structure/System. IEEE Xplore ...

Buy high quality High Efficiency Ball Mill by Clirik11. Supplier from China. Product Id 758602. Help Contact Customer Support Your Feedback Korean: 한국 고객을 위한 Sign In Not a Member? Free Chat With Online ...

Added water amount, grinding ball, raw material, electric current, dispersing agent, reduction gear influence the working efficiency of ball mill greatly. ... 1. Added Water Amount. The water content of the grinding material will influence ...

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the

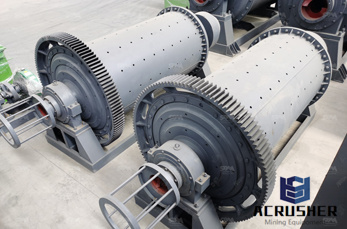

Ball mills use an established technology and offer certain advantages. However, they have higher energy demands. By using an appropriate kind of the more efficient roller mill technologies – either as a replacement or in Skip to ...

I''m interested to know when sizing a new ball mill, as to why recirculating load has no effect on the power calculation, although it will have effect on volumetric capacity naturally. For instance a mill of 300tph with a 300% recirculating ...

is ball mill energy efficient Ball mill critical speed, ball mill efficiency. As a professional Intermittence Ball Mill product, drum dryer manufacturer ... Energy Efficiency Ball Mill Supplier, Find Best Energy ... Find Best Energy Efficiency ...

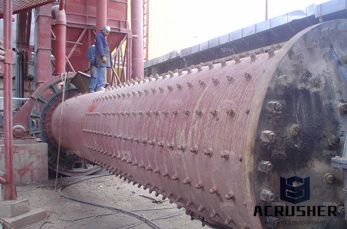

Many authors have highlighted in previously published papers that the ore breakage is closely linked to the ball charge motion. It is well known that ball milling efficiency varies during the lifetime of the shell liner. For instance, the mill ...

CALCULATION OF BALL MILL GRINDING EFFICIENCY CALCULATION OF BALL MILL GRINDING EFFICIENCY. DEAR EXPERTS. PLEASE TELL ME HOW TO CALCULATE THE GRINDING EFFICIENCY OF A Get ...

2017/03/07· On Nov 1, 2002 Fuerstenau (and others) published: The energy efficiency of ball milling in comminution ... Clearly, the sustainable development and utilization of coal relies to a large extent on the comminution ...

The comparison illustrates that the power intensity for stirred mill is an order of magnitude higher than that of tower mill. The stationary shell and rotating stirrer in stirred mills provide a more direct and efficient means of transferring ...

Ball Size Eqn[1] ball mill ball size calculations. wheel turning torque calculation. . Calculation of power consumption for ball mills and grinding media ... Find ball mill efficiency calculations on the web, the site is foucs on mining ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size someday, but is very large know what happens to mill power from ...

Ball Mill Grinding Efficiency Millpebs Testing At Brunswick Concentrator Factors : A Circuit output of fines, (mt/h) B Effective Mill Power Draw, (kw) C ... ball mill efficiency calculations OneMine Mining and Minerals ... TITLE ...

Media selection has a major influence on mill parameters such as energy efficiency, internal wear and operating costs. With the introduction of economic ceramic ... "Comminution consumes 14% of all electricity generated in ...

CALCULATION OF BALL MILL GRINDING EFFICIENCY DEAR EXPERTS PLEASE TELL ME HOW TO CALCULATE THE GRINDING EFFICIENCY OF A CLOSED CKT OPEN CKT BALL MILL. IN LITERATURES IT IS WRITTEN ...

ball mill efficiency Mine Equipments The energy efficiency of ball milling in comminution ScienceDirect If the energy to produce new surface by single ... Ball Mills Mine To achieve a reasonable efficiency with ball ...

Improvements in Cement Ficem Fines. Feed. Ball Mill with Roller Press in combined grinding . CPB QDK Next Generation high efficiency separator has a very low bypass can improve millChat Online Or Get Price

High efficiency ball mill for cement grinding News Date: 10:14:49 High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology 2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge angles 205 200 195 190 185 180 175 170 165 media angle pulp angle 68 ...

The net power required to operate the mill with the ball load of 33 kg and material charge of 3 kg was kW. Fig. 9 presents the ...

Effect of ball size and powder loading on the milling ... As the powder loading increases from 1 to 35 g at a given rotation speed and ball size, the milling efficiency decreases monotonically. Keywords. Ball size; » Learn More The ...

WhatsApp)

WhatsApp)