WhatsApp)

WhatsApp)

CEMENT GRINDING OPTIMISATION ... The world energy consumed for cement production is similar to ... The basis for modeling the twocompartment ball mill is the .

Energysaving cement ball mill | PDF Flipbook. Energysaving ball mill change the original mill structure, body, chassis integration, and installation can be a one ...

Ball Mill,Cement Mill,Cement Kiln,grind mill,rod mill,rotary kiln supplierChina Henan Zhengzhou Mining Machinery Co. Ltd. We offer you firstclass equipment and ...

Ball Mill,Cement Mill,Cement Kiln,grind mill,rod mill,rotary kiln supplierChina Henan Zhengzhou Mining Machinery Co. Ltd. We offer you firstclass equipment and ...

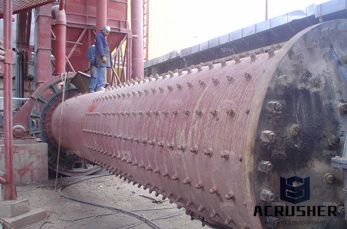

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Ball Mill Heat Balance Explanation. The Cement Grinding Office. The ... Cement Technology; Technical Forms; Simulation; Test and Diversion; Mining Area. Home .

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

Energy Saving cement ball mill, dry wet ball grinding mill price for sale,US 4,000 20,000 / Set, New, Ball Mill, AC from Zhengzhou Huong Machinery ...

OK™ cement mill. 2 Application advantages Proven commercially, the OK™ mill is ... 3050% less energy than ball mill systems Simple layout and fewer

Energy efficient ball mill is suitable for nonferrous metals and ferrous metals processing plant, it can also be used in largescale cement factory, refractory ...

Cement mill Wikipedia, the free encyclopedia. Typical mill power consumption for various degrees of fineness. ... with the cement finished in a single chamber ball ...

Cement Ball Mill, a type of Grinding Mill, is a cylindershaped device used to grind materials like ores, chemicals, ceramic raw materials and paints.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Energy Saving Ball Mill Machine Hot Sale 2017,US 9,600 980,000 / Set, New, Ball Mill, AC from Luoyang Zhongde Heavy Industries Co., Ltd. on

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... quantify ball mill design parametersto reduce energy requirement for clinker grinding ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Energy Saving Cement Ball Mill for Clinker Grinding Plant,US 1,000 100,000 / Set, New, TPD, Henan, China (Mainland).Source from Henan Zhengzhou Mining ...

The energy saving ball mill is a horizontal cylindrical rotating device, which has two cabins. Ball mill is energy saving grate ball mill and the outside runs along ...

Xinguang provide verious kinds of ball mills, such as large cement mill, Small/Medium cement mill, dry latticetype cement mill, wet latticetype cement mill.

Cement Production Line Capacity: 50 t/d3000 t/d Application: Cement Plant Main Materials: Limestone,Clay ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the ...

In order to make cement ball mill also play energy conservation and emission reduction effect, and we will be in energy conservation and emission reduction of cement ...

The energy saving measures of cement ball mill are to follow The use of advanced grinding process equipment to realize energy saving Domestic vertical mill, roller ...

So how to reduce power consumption cement ball mill system do? 1. Reduce the cement mill system power consumption from the material particle size, moisture content ...

WhatsApp)

WhatsApp)