WhatsApp)

WhatsApp)

Characterization of HighEnergy Ball Milling of Bexaferrite ... Particle size distribution is showed on Fig. 2 for all ball to powder ratio used and milling

BALLMILLING OF TiO2 AND ZrO2. of particles to nanometric values (d < 100 nm) depended on powdertoball weight ratio. The milling of TiO2, ZrO2 and their mixtures ...

ball milling ball weight powder ratio . Download as PDF InTech Apr 19, 2011 reactant powders, especially the processing factors such as milling speed, ballto ...

ball to powder ratio ball mill. provides both small ball mill and big ball mill; each new and utilized ball grinding generator. For medium natural powder .

Why the ball to powder ratio (BPR) is insufficient for describing the The ball to powder ratio (BPR) is a processing parameter that is frequently used in both

ball to powder ratio in mill FDP. what is ratio balls in vertical ball mill. ... Cement Vertical Mill vs Ball Mill the ratio between mill airflow rate and separator ...

... for preparation of polymer composite material by ball milling? ... Ball to powder ratio: ... Best way to determine the balltopowder ratio in ballmilling?

milling have been analysed and the calculated ball trajectory is compared with insitu observations of ball .. function of the milling ratio R ... ball to powder ...

REDUCTION RATIO FOR BALL MILLING. Posted on May 3, ... A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

Closed circuit systems for ball mills | Industrial . The coarse powder is returned to the ball mill and ground again by changing the circulation ratio and the Closed ...

Planetary Ball Mill Process in Aspect of Milling Energy Journal of . This paper reviews the theories of milling energy in planetary ball mill process based on the ...

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball ... ratio of powder to ball ... powder loading on the milling ...

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure ... ball to powder ratio, temperature of milling and intensity of

Abstract Effect of milling time and ball to powder weight ratio (BPR) were investigated on the phase transformation of monoclinic zirconia during high energy ball ...

ball mill steel ball charge YouTube 11 Feb 2014 ... More ... results are achieved using a high ball to powder ratio and big milling balls. Original ...

Best way to determine the balltopowder ratio in ball . Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the ballto ...

Ball mill Wikipedia . A ball mill is a type of An internal cascading effect reduces the material to a fine powder. Industrial ball mills It becomes a problem if the ...

Ball To Powder Ratio In Ball Mill Crusher USA » ball to powder ratio in ball mill » ball mill determine top ball charge » 20mm ball for a ball mill perth » what ...

A ball mill is a type of grinder used to ... of steam power that an effective ball milling machine ... material to a fine powder. Industrial ball mills can ...

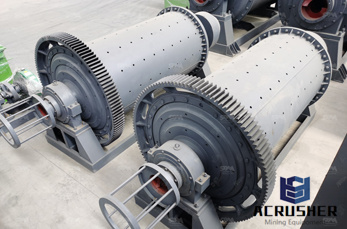

Ball mill is a key equipment to grind the crushed materials, widely used in the manufacture industries, such as cement, new building material, refractory material and ...

Effect of Ball to Powder Weight Ratio on the SciELO. May 29, 2012 MoSi2TiC nanocomposite powders were successfully synthesized with different ball to powder .

ball and material ratio of ball mill ratio – SAMAC. 7842 USD. Circulating Load Ratio ... ball to powder ratio in ball mill pdf reader | Material processing.

ball milling ball weight powder ratio ZCRUSHER . The effects of ball milling and molar ratio of LiH on the ... Download the PDF for The effects of ball milling and ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

WhatsApp)

WhatsApp)