WhatsApp)

WhatsApp)

Effect of ball size change on the performance of ... In order to optimize ball size distribution inside the mill, ... for one of the ball mills and its efficiency in ...

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

Theory and Practice for . Jar, Ball and Pebble Milling . ... a ball mill is referred to as ... efficiency of operation

Ultrafine Grinding of Inorganic Powders by Stirred Ball Mill: ... role in determining the grinding energy efficiency for mill ... grinding ball size.

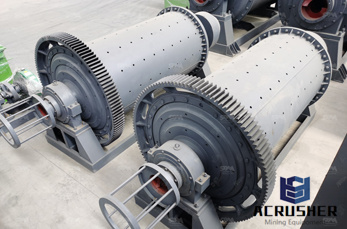

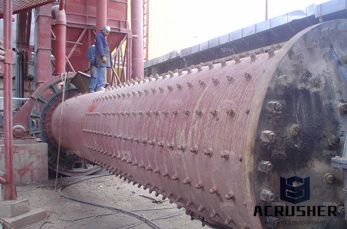

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on ... The size of a mill is usually characterized ...

Five Steps to Increase Ball Mill Efficiency College Essays wang The ball mill is the key equipment for grinding after the crushing process, which is widely used ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ... Ball size distribution inside an industrial mill was ... Figure Ball size distribution along the mill length ...

This greatly reduces the grinding efficiency of the mill and in some ... Double Roll Drive Rolls for Rod / Ball Mill ... Size Reduction. Barrel Mill; Rod/Ball ...

Ball Mill Download as Word ... grinding efficiency of the mill and. it is especially ... products are not up to the qualified size requirements. the ball of mill ...

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale ... size, ball mill was ... powder loading on the milling efficiency, ...

consisting of a tube ball mill and a high efficiency separator was introduced through ... How do you calculate ball mill ... Ball mill, Ball size effects ...

Calculate and Select Ball Mill Ball Size for ... Find ball mill efficiency calculations on the web, the site is foucs on mining equipment tech. Readmore.

Milling Efficiency Balls Size ... The model of the relative capacity as a function of circulating load and classification efficiency for secondary ball mill ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

Ball Mill Costing Calculation . ... ball mill efficiency calculations OneMine Mining and ... ... the ball size in the ball mill ...

ball mill grinding efficiency. ... Ball Mill,Cement Mill,Cement Kiln,grind ... standard for precision hammer mill grinders and controlled particle size reduction ...

with each size, ball mill was carried out for 12 h at three ... Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ...

effects of grinding media shapes on ball mill performance. grinding. Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes.

Affecting Size of Product from Ball Mill. . affect the grinding efficiency ball mill. factors affecting grinding efficiency ball mill – Grinding Mill ...

The energy efficiency of ball milling ... data to provide an assessment of the energy efficiency of ball ... to the ball mill at any other size ...

Ball milling is one of the few unit operations that actual improve in performance and efficiency with increasing size. ... BALL MILL CAPACITY AND ... Steel Ball Mills ...

Ball Grinding Efficiency ... ball mill efficiency improvement ... Relationship of Media Size and Grinding Efficiency of Ball Mill .

Relationship of Media Size and Grinding Efficiency of Ball Mill. The ball mill crushes materials through the impact and grinding effect of the grinding media.

WhatsApp)

WhatsApp)