WhatsApp)

WhatsApp)

Effect of highenergy ball milling in the structural and, Through the process of highenergy ball milling it is possible to obtain solid materials with higher ...

The annual output of high quality grinding ball is 200,000 tons. ... advanced hot rolling ball rolling production process ... Iraeta is a SinoSpain joint venture ...

Steel Grinding Media for Mineral ... No matter what you are grinding in a ball ... Except the minority of people who use autogenous mills and pebble mills ...

BALL MILL INSPECTION ... beginning of the grinding process. ... and Performs Comparably to Media Manufactured in the Continuous Pin Mill and in Ball Mills ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

This module will cover the technology of ball mills used for raw and finish grinding in the ... for raw and finish grinding in the cement manufacturing process.

Mining Industry: What is a grinding mill? ... Engineers and other professionals often refer to the process of grinding as a unit ... Ball Mills which do fine grinding.

Grinding is the required process when size reduction of below 520 mm is needed. ... Ball Mill. Ball Mills are primarily used for fine grinding.

In the chemical and process industries, grinding is an important step in preparing raw materials for ... GRINDING MILLS. Ball mills efficient operated perform a wide ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, ... also be introduced to the mill during the grinding process to achieve the ultimate dispersing or

Ball Mills are commonly used for secondary and tertiary grinding. The designs are either overflow or grate discharge. Ball mills are the most common secondary mills ...

Introduction Ball mill (also named grinding ball) is one of the most important grinding mills in the mining industry which is used to break all kinds of minerals ...

RETSCH ball mills are available as mixer mills as well as planetary ball mills. Mixer Mills grind and homogenize small sample volumes quickly and efficiently by ...

Hosokawa Alpine. As a leading ... Powders of extremely high fineness can be produced with ball mills and agitated media mills. ... The grinding process can be ...

The grinding mills contain materials meant for ... When a ball mill grinder and grinding ball is what you need to meet ... As per process conditions: 630: 137:

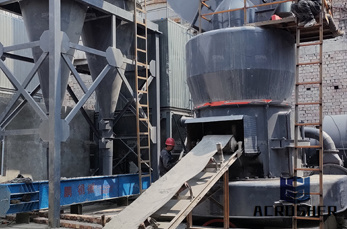

Dry Grinding Ball Mill Of Grinding Machine Equipment Process . DRY GRINDING BALL MILL. Dry Grinding ball mill is the material to be broken, and then to smash the ...

Ball Mill Overview Ball Mill is crucial equipment for grinding after materials are crushed. It is an efficient machine for powder grinding. And the ball mill is ...

Grinding mills are used to break solid ... Ball Mills. HOLDTRADE works with ... They are used extensively in the Mechanical alloying process in which they are not ...

Ball mill, an energysaving grinding device, is widely used in mineral processing, building materials and chemical industries. Ball Mill grinds material by rotating a ...

FEATURES Introduction to Ball Mill. Ball mill is a key equipment to recrush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 ...

ball mill for quartz grinding Crusher idpenghancur. Modelling the performance of industrial ball mills using sale / quartz grinding ball mill into powder in grinding ...

Autogenous mills, semiautogenous mills and ball mills for wet grinding. A company of Polysius ThyssenKrupp Technologies tk

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

WhatsApp)

WhatsApp)