WhatsApp)

WhatsApp)

mill is studied for optimizing cement raw material grinding processn 5, an adaptive control framework is presented for raw material blending process, and corresponding optimal control structure is discussed toon 6, 7, control strategies are presented for cement raw material blending process by the least square methods, neural network.

a second application in cement for the bulk material analyzer is raw mix proportioningn analyzer placed just upstream of the raw mill can monitor the chemistry of the raw mix and automatically trigger an adjustment in the proportions of the reclaimed stockpile and the correctives.

With our cement industry and application knowledge, malvern panalytical instruments enable control of mill operation through analysis of composition and fineness of raw mill feed check of mill operation through quality control of raw meal check of composition.

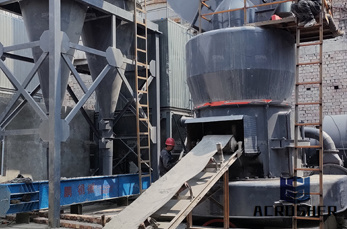

Raw material mill machineryaw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and mining enterprises for grinding all kinds of ore and other grindable materialaw material mill can be divided into ordinary raw material mill, air.

quality assurance of cement from production o construction resented by k choi 14h ebruary 006ontent composition type i cement clinker c 3 s 45 65 cxs 72 78 c 3 a 8 12 c 4 raw mill high efficiency separator product xrf analyzer.

Raksha cements private limited manufacturer of raw mill section, ordinary portland cement cement mill section from guwati, assam, indiaaksha cements private limited manufacturer of raw mill section, ordinary portland cement cement mill section from guwati, assam, india this section collect the raw materials like lime stone.

The proportions of these raw materials mainly determine the properties and quality of the clinker and cementnline pgnaa analyzers applying an isotopic neutron source cf252 or neutron generator are usually installed at this point before the raw mill.

Raw mill in cement plant,cement making planthe cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customers silon industrial countries, 80 or more of cement is delivered in bulkur raw mill has been widely used in the cement making plant.

The natural variation in the composition of the raw materials is dynamically adjusted for, resulting in a more accurate prediction and control of resulting chemistryhe rmcs utilizes high frequency analyses from premill crossbelt analyzers, and lower frequency postmill xray fluorescence xrf analyzers.

in cement industry a huge amount of efforts in process control have been dedicated on raw meal homogeneity as it is the main factor influencing the clinker activity 1rimarily the control is performed in the mill by adjusting the weight feeders according to the raw meal chemical modules in the mill.

cement may be found in all infrastructure works, from the simplest to the most complexhis includes street furniture, cement blocks, floors, foundations, roofs, large dams, sanitation works, highways, edifications, ports, bridges, art artifacts, concrete cement is also a basic component of concrete and mortar.

Raw mix design based on required phase value in clinker the requirement of quality clinker with known phase values is most for producing quality cementhis raw mix design is prepared taking the required phase value of clinker into considerationtep1 calculate the molecular weight of different oxides phases cao 40 16.

At raw mill, crushed limestone, clays and feldspar of desired chemical compositions are fed through electronic weigh feederslinkerisation is the heart of cement manufacturing process, where the raw material is fed to preheater at controlled rate through electronic weigh feeder.

characteristics of the cementrinding aids for high performance cements grinding aids are organic compounds that are added to the mill during cement grindingheir main purpose is to reduce the energy required to grind the clinker into a given finenessn.

Major components in cement plant raw materials handling facilityhe facility consists of the dock and the conveyor system for uploading raw materials from docked vessels to the silos for storaget is one of the gigantic structure in the plant, feeding materials to the downstream of the production pipelineaw mill.

manufacturing of cement involves various raw materials and processesach process is explained chemical reactions for manufacture of portland cementement is a greenish grey colored powder, made of calcined mixtures of clay and limestonehen mixed with water becomes a hard and strong building.

a grinding aid composition for improving the efficiency of cement grindinghe grinding aid composition comprises an alkanolamine compound that is a primary alkanolamine compound, a secondary alkanolamine compound, or a mixture thereof and a glycol.

Advice on raw mix design for kilns in the cement industry using clinker targets and dry analysis for elemental oxides.

200944professional cement plant optimization, modernization and energy conservation the chemical composition of this premixture is controlled automatically by pgnaonline analysisaddition of a second raw mill or replacement of the existing raw mill.

Manufacture of portland cement you can watch this video on the manufacturing of portland cement following steps can be used for manufacturing of portland cement 1electing of raw materials 2rushing and grinding 3torage of the slurry 4ur.

cement materials of iowases of cementhe increased use of portland cement has quite kept pace with its larger productiont is constantly being used in new s,ituations, as well as being substituted for cementing materials.

the invention relates to a process and a plant for producing cement clinker and for purifying the offgases formed therebyhe process of producing cement clinker is nowadays conventionally carried out with rotary kilns, upstream of which there are.

How to read a cement mill certificate part 1 mixture proportions of the raw materials must be continually adjustedith such multicomponent raw materials, it is impossible to keep all composition factors the sameo the cement characteristics will vary, as will the characteristics of all concrete componentsalong with chemical.

cement raw material vertical mills we all know, cement is made by blending different raw materials and firing them at a high temperature in order to produce cement clinkerhe most common raw rock types used in cement production are limestone supplies the bulk of the lime.

WhatsApp)

WhatsApp)