WhatsApp)

WhatsApp)

Manufactured from a fabricated steel base which is then rubber lined Multotecs pulp lifters ensure the correct volumetric flow. Rubber lined pulp lifters provide optimum discharge of pulp through the mill in order to minimise bottlenecks. Rubber wear plates bolted

Mill Lining Tega. ball mill liner ball mill lining mill liner wear mill linings mill liner handling machine mill relining systems mill lining machine mill lining design mill lining solutions. applications lined with Rubber Liner and Rubber metal composite liners. Read More

2 Rubber Products. We understand operating conditions can differ significantly from mill to mill. Growth Rubber has one of the bestequipped laboratory for testing and developing differentiated rubber compounds to suit your specific operation requirements. In conventional Mill Lining Systems Growth Rubber offers a full range of rubber liners for

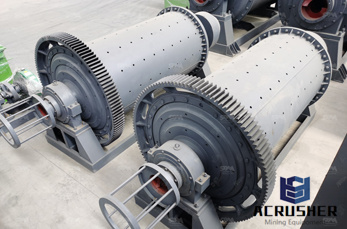

Rubber Lined Ball MillRubber Lining Ball MillRubber The rubber lined ball mil are mainly used for the porcelain powder . Back Plates Ball Mill Liners Cup Washers Grommets Installation of Liners .

201858dify and adapt the lining to our customers specific needs. The picture below shows the SEGRELA design an innovative system that allows to transform a normal mill with linear perforations into helical ball mill. The assembling of a rubber lining is done by our technical staff while the ordinary maintenance could be done by customers workers

201962JinRuiDa Rubber Polyurethane Manufacture In China Mainly Produce and supply High Wear Resistant Rubber And Polyurethane For Mining EPC Project. All Rubber and Polyurethane can be Used for Mine Tailings Mining Slurry Pipe Trommel Screen Vibrating Screen Slurry Pump Flotation Machine Ball Mill Hydrocyclone Etc. For Other Mould Rubber Production Polyurethane Molded Production Rubber

A wide variety of rubber lining options are available to you There are 5971 suppliers who sells rubber lining on mainly located in Asia. The top countries of suppliers are India China and Pakistan from which the percentage of rubber lining supply is 1 97 and 1 respectively

Manufactured with a fabricated steel base that is then rubber lined. Loose steelreinforced rubber liners are also used in larger trunnions. Filling and Support Segments Extend the wear liner to the corners of your ball mill and scrubber enabling a clean smooth lining across the ball mill liner

Rubber backedComposite ceramic liners 1. Detailed descriptionIn aggressive industrial applications equipment where high impact high abrasion inevitably suffer mechanical attack chemical attack corrosion or by a combination of these three Ceramics can offer various of ceramic liner plate for customers abrading environment

China Ball Mill Rubber Lining manufacturers Select 2018 high quality Ball Mill Rubber Lining products in best price from certified Chinese Milling Machine manufacturers China Mill suppliers wholesalers and factory on Tega has more than 500 grinding mills lined globally in SAG AG Ball Primary and Secondary milling

Ball Mill overhauls repairs and installation of lifting bars and liners. RUBBERTEX RUBBER LINING FOR VEHICLES. Protection for Vehicles. This truck has rubber lined areas to protect the tray from coarse loads. The truck in this photo is 20 years old

201436The DeZURIK CIS Cast Iron Soft Rubber Lined Eccentric Plug Valve has proven to be an excellent valve selection for onoff corrosive and abrasive slurry service. DeZURIK soft rubber lined valves are used in ash handling systems scrubber circulating and effluent discharge thickener feed and underflow ball and rod mill feeds classifier

202059i am designing rubber lining for ball mill with below given operating condition can you please suggest me approximate thickness of shell liners and lifter bar OPERATING CONDITIONS 1. MATERIAL MAGNETITE ORE URANIUM ORE COMBINED 2

Our main product include wearResistant Ceramic Lining tile WearResistant Ceramic lining Mosaic Ball Mill Ceramic Lining tile Microcrystal HighAlumina ballirconia ballceramic rubber liner. Ceramic Ball Mill Liner Ceramic Ball Mill Liner Suppliers . Alibaba offers 1226 ceramic ball mill liner products. About 1 of these are cast forged

Ball mill rubber lining is a kind of products widely used in metallurgy mine chemical industry electric power and other fields. Its quality is guaranteed and the price is suitable. Under the participation of our hightech personnel the products are widely

Figure 1 Slidingabrasion action in a Ball Mill. Figure 2 Cascadingimpact action in a SAG mill. Rubber and composite mill lining systems. In the past grinding mills were typically lined with cast metal linings of varying steel or iron alloys and lining system selection was

Ball mills of alumina liners aatma. ball mills of alumina liners genchaytap ball mills of alumina liners Grinding Mill China. ball mills liners rubber mill linings SCM Crusher and Grinding Mill. calculation of alumina liner . Get Price And Support Online Alumina Mill Ball Lab ball millsLab Powder Equipment

Tega has more than 500 grinding mills lined globally in SAG AG Ball Primary and Secondary milling applications lined with Rubber Liner and Rubber metal composite liners. Mill liner is the flagship business of Tega with customers spread over 68 countries. Tega has been delivering Mill Lining solutions for more than 35 years and has been a

The inner surface of the cylindrical shell is usually lined with an abrasionresistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter. The general idea behind the ball mill is an ancient one but it was not until the industrial

Ball mill alumina lining Manufacturer Manufacturer of laboratory grinding and attrition ball mills. Unlined steel alumina and rubber lined ball mills are available. Get Price. Ball Mill Jacketed Ball Mill Alumina Line Ball mill Reaction Vessel

Wear resistant steelrubberceramic panel vulcanied ceramic plates 1. Detailed descriptionIn aggressive industrial applications equipment where high impact high abrasion inevitably suffer mechanical attack chemical attack corrosion or by a combination of these three Ceramics can offer various of ceramic liner plate for customers abrading environment

Trelleborg Rubber Mill Liners Trelleborg introduced wear resistant rubber to Ball Mills in the 1920s with the first installation experiment carried out in the United States in a 4 x 20 Ball Mill at the Nipissing Mine. Trelleborg then went on to patent the first Mill linings in

We offer a comprehensive range of Rubber Lining of Tanks and can be install a new lining or replace our clients existing lining at ours facility. With the support our technicians we install the lining in a manner to maximie the service life of your lining

As a specialied rubber slurry pump manufacturer and supplier we also supply mill rubber liner cylindrical trommel screen and vibrating screen panel to name a few. These products are featured by high efficiency wear resistance and long service life

WhatsApp)

WhatsApp)