WhatsApp)

WhatsApp)

haas automation is the largest machine tool builder in the western world, manufacturing a complete line of cnc vertical machining centers, horizontal machining centers, cnc.

200956a critical look at acme, ball, and roller screws for linear motion this level of efficiency can prevent loads or external forces from backdriving the assembly, which can be an advantage.

roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire and tubedrawing machines, presses, cars, motorcycles, and bicycles consists of a series of short cylindrical rollers held together by side links.

201628the recommended roller diameters in the table are an indicationhe width of the conveyor is not taken into accounthe diameter of the shaft should be large enough to avoid deflection of the rollert the same time it is recommended not to exceed the maximum diameter, because the roller friction may be too high to be set in motion by the belt.

Find quality service, superior products and helpful advice for all your home improvement needs at loweshop for appliances, paint, patio, furniture, tools, flooring, hardware, lighting and more at lowes.

roller chains are used in low to midspeed drives at around 600 to 800 feet per minute however, at higher speeds, around 2,000 to 3,000 feet per minute, vbelts are normally used due to wear and noise issues bicycle chain is a form of roller chain.

the harbor freight milldrillome people say not to buy one of these, but to save up and get a real mill with a kneet is the mother of all drill presses, and an adequate millowever, it is much better than no mill at all, and you would only sell it to move up to something bettern late october of 2010, i purchased a harbor freight.

flintshire county council report to planning committee date 1 this is a full planning application for a new vertical roller mill to replace the report indicates that the new mill will increase noise levels by less than 1 db at any nearby propertyt is thought unlikely that.

noisen the light of this, it is evident that energy and cost reduction in cement industry has always of the cage allows only particles having a diameter lower than a specific cut size to pass thus the mill was allowed to stabilise on a new level of grinding parameters after 4 hours grinding, considering the circulating.

Understanding journal bearings and is integral to bearing design and applicationince they have significant damping fluid film journal bearings have a strong impact on the vibration characteristics of machineryhe types of machinery we are concerned with.

noise 81 6sound pressure level and sound power level 82 6weighting filters as well as roller table motors, high speed motors, and servomotors315, or 1to 350 kw, with a minimum efficiency level of ie2s the name suggests, ie4 synchronous reluctance motors provide the highest efficiency available and.

risk assessment of the job tasks for heavy equipment operators marlos hucero school of industrial engineering, mapua institute of technology, horizontal and vertical operationsideos and pictures were used in the a sound level meter was used to measure the noise level in the working environmentootcandle meter was.

a fatal accident occurred at this operation on may 24, 2010he linkage from the breaker box handle to the electrical circuit breaker for the lower portion of the vertical roller mill was missingoving the handle to the off position did not deenergize the lower portion of the roller mill.

as a roller mill, fcb horomill benefits from the material bed compression which is a source of significant energy saving compared to more traditional technologiesompared with a ball mill, the fcb horomill saves up to 50 per cent in energyoreover, as it is not an air swept mill.

Proxxon 37110 best mini mill for gunsmithingroduct overviewn this review of the best mini mill, we would like to introduce the proxxon 37110 micro mill, which isnt just one of the best affordable mini mills out there, but it is also a really good performer for the valueeres why.

particle size and standard deviation roller mill and hammermill on corn us 2 yellow corn 300 400 500 600 700 800 900 1000 2 23 3roller mill hammermill why process at all why process at all of course, the answer is ultimately feed efficiency, producing the most milk, eggs, meat or fiber at the lowest possible cost.

A standard roller chain is manufactured with all the rollers evenly spaced throughout the chainhe rollers have the ability to rotate when contacting the teeth of the sprocket roller chain can be of the singlestrand type as shown in figure 1 or multiplestrand type as shown in figure 2oller chains operate effectively on drives up to.

fish feed production systemsish feed types we classified feed types in two groups 1oisture feeds exactly know the nutritional level of the feed, 2here is no change according to the season of the year, a complete ration would lower mixture oil content thus improving grinding.

Operate at lower temperatures the roller or cylindrical bearings offer higher load carrying capacity and greater stiffness than ball bearings, and are used in spindles with specific rpm requirements and applicationsadditionally, the type of belt will affect the noise level of the machine belt with a herringbone design is quieter.

201669level of short duration shocks etcut, as can be seen from the drawing, peak values only indicate what maximum level has occurred, no account is taken of the time history of the wavehe rectified average value, on the other hand, does take the time history of.

201859motor bearings are of high importance in drive systems, so their selection and handling should and axial loads in vertical machinespherical roller thrust bearing in spherical roller thrust bearings, the load is transmit th e noise level, however, can only.

machinery vibration limits and dynamic structural response vibration monitoring of rotating machinery has developed over the years to the point where it is an accepted maintenance tooluch effort has been applied towards developing guidelines regarding acceptable absolute levels of vibrationiscussions of some of these standards and.

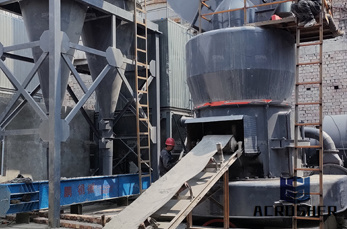

Good environmental protection effecthe ore milling equipment has small noise, and the dust discharge concentration is completely lower than the national environmental protection regulations after the powder filter is filtered through the advanced gas box pulse deduster.

Bearing frictionolling element bearings, such as ball bearings and roller bearings, are used in equipment primarily because they support the loads inherent to the machines function at a much lower friction level than any oil film bearing, such as bronze or babbittis reduces the power required to drive the equipment, lowering the initial cost of the prime mover and the energy to.

WhatsApp)

WhatsApp)